SphereOx

1.Reduces casting defects including carbon defects

2.Reduces total cost

3.Requires less resin binder

4.Increases mold tensile strength

5.Has excellent flow properties

6.Eliminate need for Specialty Sands

7.Enhances mold permeability

8.Reduces blow tube and vent plugging

9. No dust….improves work environment

SphereOX®: the cost-effective additive to eliminate veining, penetration, pinholes, and lustrous carbon casting defects.

Nothing works better than SphereOX® at reducing casting defects in no-bake and resin coated sand mold/core applications. SphereOX® is the ideal additive to minimize the use of costly gas generating resin binder systems while enhancing mold strength!

• Reduces casting defects

• Lowers cost (reduced binder, lower cleaning room cost, lower scrap rates)

• No dust…enhances work environment

The best additive for no-bake molds and cores and resin coated shell sand just keeps proving itself time and again!!!

One of the highest potential cost factors of an iron, steel or bronze foundry is casting rejects and casting cleanup cost. Sand, binder system, and sand additive selection can most readily control this cost.

SphereOX is the only spherical foundry sand additive developed and produced for the foundry industry. It is a synthetic additive, which is consistently more pure then natural oxides. When used as an additive in foundry cores/molds SphereOX significantly reduces surface defects and improves the quality of the castings. It has excellent flow properties and requires less resin to achieve the required mold core bond strength.

SphereOX is typically added to no-bake foundry molding sand systems as an additive at 2% to 8% by weight for the following intended purposes:

1. Improve the surface finish of an iron or steel casting

2. Eliminate veining on a casting

3. Eliminate penetration of metal into the mold

4. Eliminate pin-holes resulting from gas entrapment

5. Eliminate burn-in and burn-on

Foundries that use SphereOX have reported increased productivity by eliminating cleaning room work through elimination of persistent veining, penetration, and pin-hole pr****

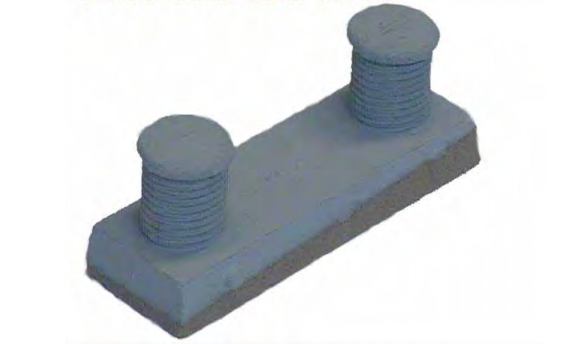

The addition of 8% SphereOX to the core sand system made it possible to cast threads in a Wear Resistant Iron Casting (Wear Hammer) with no casting defects!

Core produced by Magotteaux Foundry, Monterrey, Mexico for “Cast in Thread” bolt hole.

You can achieve similar savings in machining and cleaning room costs by using SphereOX for iron, steel or bronze castings.

SphereOX’s unique manufacturing method results in a predominantly spherical shape of unique physical and chemical characteristics. SphereOX is the only predominantly spherical, extremely pure sand additive. SphereOX contains higher FE content than any other commercially available oxide product. It is a finely balanced, critically sized, ferrous product predominantly consisting of Fe3O4.

There are no binders, glues, or other ingredients added to SphereOX that would increase surface area or add hydrocarbons or any other volatiles that could create gas during casting. In fact, to our knowledge, only SphereOX produces a gain on ignition (GOI) of approximately 10% when heated which proves its capability as a gas scavenger. Most common defects are caused by parting of molds (veining), gas entrapment (pin-holes), iron or steel penetration (burn-in and burn-on), lustrous carbon (excessive carbonaceous material) and mold expansion (critical dimension). SphereOX eliminates these problems.

No-bake resin systems that hold the mold together produce gases. Resins are formulated to provide greater adhesive strength than cohesive strength. The stronger the mold the less chance of parting, minimizing the quantity of high cost resin but obtaining full coverage one molecule thick is the objective. Round sand and round SphereOx maximizes the possibility of obtaining that objective because a round shape minimizes surface area. Foundry technicians are encouraged to inspect SphereOX under a microscope and compare it to competitive iron oxides or any other proprietary foundry sand additive. Notice the significant difference in shape, uniformity of size, and lack of dust when comparing it with any other additive. It is suggested that the foundry perform tensile strength comparisons of SphereOX against other additives using varying amounts of additive and reducing amounts of binder system. Typically, reductions of 10% or more binder are possible at comparable or higher mold tensile strengths when using SphereOX compared to other additives. Reducing binder reduces the quantity of generated gas and generated VOC’s and HAP’s during casting!!!

SphereOX’s spherical shape also allows the passage of harmful gases from the metal/mold interface. Competitive products which are dusty, absorbent, granular, and flake-shaped tend to act as a physical barrier at the mold/metal interface, plugging the mold and preventing beneficial mold gas permeability.

Mold dimension stability is critical for castings. SphereOX has a much higher specific gravity and higher thermal conductivity than sand resulting in more rapid chilling at the mold/metal interface. Rapid chilling assures casting dimension stability. In some cases, SphereOX can be used with silica sand to replace zircon sand. Usually higher percentages of oxide are required such as 5 to 8% by weight.

SphereOX has a neutral (7.1) pH; thus it is compatible with most binder systems. It is available in three size ranges and as a special order, fine minus 325 mesh.

No other additive provides the flowability that is achieved with SphereOX. Conventional iron oxide tends to bridge and flow unevenly in feeder systems resulting in non-uniform distribution in the batch. Non-uniform distribution of additives causes large variations in mold capabilities that may cause casting failures or defects. Typically foundries use extra additives to compensate for poor mixing which only results in higher cost and more variability in the final product.

Naturally occurring magnetite or hematite may contain high percentages of other non-desirable elements such as lead or other heavy metals. Hematite (FesO3), red iron oxide, may be good as a coloring agent or a source of oxygen, but hematite iron oxide is not as efficient as SphereOX because the red iron oxide is in its most stable state and cannot act as a scavenger of gas. Also, it is typically sold as a fine powder which absorbs resin. Proprietary additives and competitive grades of black iron oxide may contain carbonaceous material, or other volatiles, which could convert into gases during casting that cause veining, pin-holes and lustrous carbon defects. It is interesting to note that new SphereOX has a carbon content of .05% but after casting the carbon content of SphereOX increased to .7% to .9%. This would indicate that scavenging of carbon takes place and may explain how SphereOX helps cure lustrous carbon defects.

Mold tensile strength is critical to quality castings. SphereOX provides higher mold strength than any other additive. This not only reduces veining but also flaking or spalling. Typically additions of 2% to 5% are sufficient to prevent flaking, veining, pinholes, or spalling. Comparison of tensile strength and trials using SphereOX at various additive levels is recommended.

As many of our satisfied customers suggest, “Ask your foundry workers.” Foundry workers love SphereOX. It is virtually dust free, non-staining and thus provides a much cleaner work environment.Chesapeake Specialty Products, Inc. has Market Specialists and an established organization of qualified distributors that specialize in foundry systems.

LESS COST and FEWER DEFECTS

SphereOX® vs. Conventional Sand Additives

1. SphereOX® is cleaner, scavenges gas, and increases flowability of sand

2. Less Surface Area requires less Resin

Typical Sand Additive use:

Competing additive(like Veino® or Veinseal®) 2% in Mix at 33¢/lb.

SphereOX® 2.7% Oxide in Mix at 23¢/lb.

Typical Resin use:

With competing sand additive (like Veino® or Veinseal®) 1.3% at $1.00/lb.

With SphereOX® 1.0% at $1.00/lb.

For 1 Ton Batch:

Sand $70.00/ton delivered = 3.5¢/lb.

Savings of approximately 7%