Lake Sand

Lake Sand

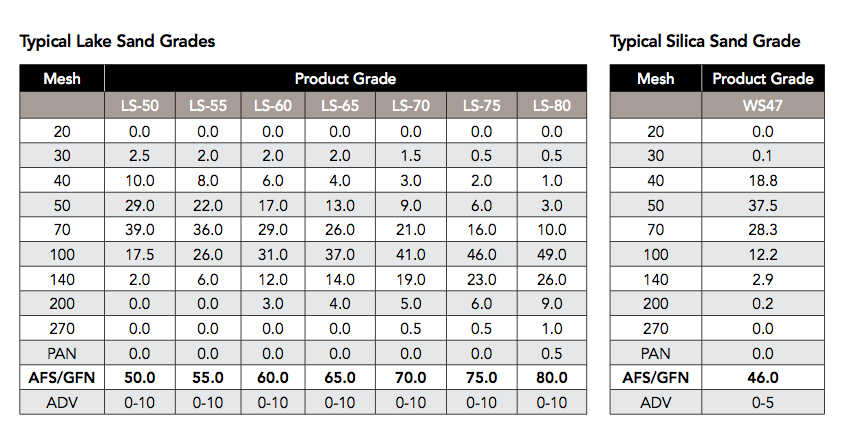

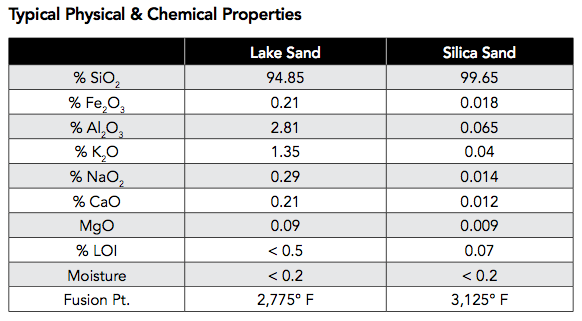

Fairmount Foundry is the leading producer of LakeShore & Wexford lake sands for the Foundry Industry. The sub-rounded shape and natural oxides make our lake sands ideal for iron foundries. No other type of sand has the excellent anti-veining characteristics of lake sands, enabling foundries to eliminate expensive additives and instead rely on the consistency of the lake sands. These fine bank sands also perform well as additives to green sand systems.

Features & Benefits

• Excellent performance in green sand systems

• Superior anti-veining properties

• High quality with cpk’s that exceed 3

• Extremely consistent and low ADV (>5)

• Finer lake sands make an excellent molding addition

• Washed and dried for better coating of the binder to the grains

• PLC controlled blending ensures consistent particle size distribution

We can blend any of our sands to create the product that best meets your specific requirements. For example, silica/lake is a superior blend for core making, with low binder levels that may not require anti-veining additives.

Lake Sand

Sub-rounded shapes and natural oxides make our lake sands ideal for iron foundries.

• Excellent performance in green sand systems

• Superior anti-veining properties

• Extremely consistent and low ADV

• Controlled blending ensures consistent particle size distribution

Silica Sand

This high-purity round grain sand is ideal for all types of foundries. Grain shape and high-purity silica content results in low binder percentages for cores and molds.

• Available in round or sub-round grain shape

• 99.65% SiO2 purity for high refractoriness

• 3,125° F Fusion Point is ideal for steel castings

• 4-screen distribution available for higher density molds and cores

• State-of-the-art blending ensures a consistent silica grade

• Other silica sands available upon request

• Custom blended sands can be developed to meet your specifications

• Delivery available in pneumatic and dump truck

• Lake and silica sands can be blended

• Lake sands can be supplied damp

Warning

Contains Free Silica. Do Not Breathe Dust. Prolonged exposure to dust may cause delayed lung injury (silicosis). Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Humans (vol 68, 1997) concludes that there is sufficient evidence in humans for the carcinogenicity of inhaled crystalline silica in the forms of quartz and cristobalite (Group I) in certain industrial circumstances, but that carcinogenicity may be dependent on inherent characteristics of the crystalline silica or on external factors affecting its biological activity or distribution activity or distribution of its polymorphs. See Material Safety Data Sheet for detailed information. CAS 14808-60-7 FOR INDUSTRIAL USE ONLY.

Important

The technical data herein is believed to be accurate. It is offered for your consideration, investigation and verification. Buyer assumes all risk of use, storage and handling of the product.