Resin Coated

Technisand

Our TechniSand™ resin coated shell sands are specially formulated to reduce emissions, smoke and odor, while delivering the same high casting quality and productivity as conventional sands. They also significantly lower hazardous air pollutants (HAPs), volatile organic compounds (VOCs), and free phenol. With TechniSand, you don’t have to sacrifice performance to create a better environment in your plant or in your community.

Features and Benefits

Increased Productivity

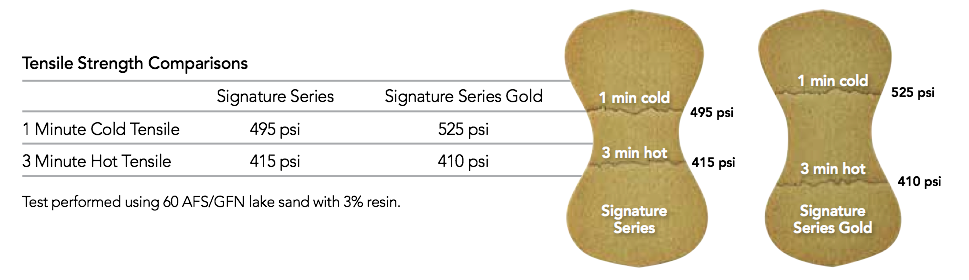

Signature series products provide higher tensile strengths and greater uniformity than other shell sands, which leads to a long list of benefits.

• Reduced wall thickness

• Better heat transfer capabilities

• Reduced sand usage

• Shorter invest cycle times and cure times

• Higher melt points improve flowability and finish

• More uniform curing

• Better shakeout properties

Reduced Scrap

• Reduced lamination and peelback defects

• Greater core strength for reduced breakage

• Lower Loss on Ignition for fewer gas defects

Reduced Hazardous Air Pollutants and Smoke

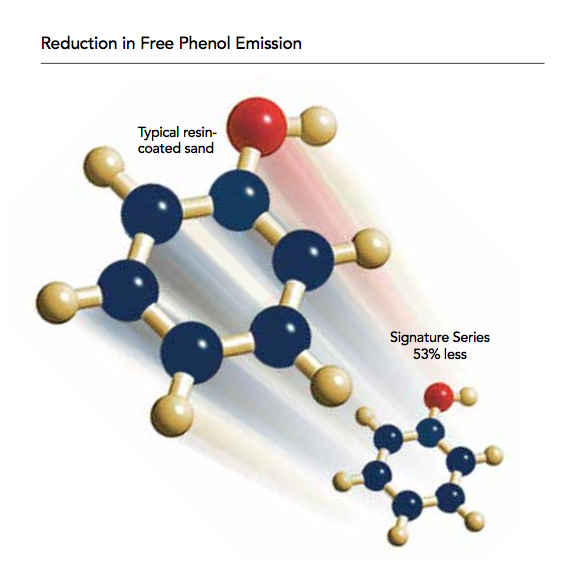

• The first resin-coated sand product specifically designed to reduce free phenol emissions

• Neozien Technology additive eliminates ammonia odor.

• Signature Series Gold product reduces HAP’s, free formaldehyde, and free phenols even more

We Know the Products, Processes, and Markets

Our highly experienced technical staff helps you choose the right products and blends to assure better casting quality and higher ROI. We conduct a comprehensive audit of your sand system with no obligation.

No matter what type of metal castings you are producing, Signature Series resin-coated sands will out-perform typical resin-coated products. For aluminum castings, our specially formulated additives provide high tensile strength at very low resin levels, for superior shake-out properties.

We Provide the Widest Variety of Coated and Blended Sands in the Industry

Regardless of your specific requirement, Fairmount Minerals delivers a product suited to your needs. Custom sand and additive formulations are designed for each customer. Blends are created to improve permeability. Cushioning agents are added to eliminate veining, and iron oxides are added to eliminate warping. Blends of silica sand, lake sand, and ceramic material are also available.

Our Signature Series products are pre-coated and ready to use. You get all the benefits of resin-coated sand without the associated capital and operational costs of sand/resin mixing systems.

A Better Binder Technology

TechniSand Signature Series out-performs cold box, warm box, and no-bake in several areas. Signature Series resin-coated sands deliver benefits such as:

• Consistent and high tensile strengths versus other binder processes

• The best dimensional tolerances

• Excellent casting surface finish

• The ability to produce complex cores at a very low core weight

• Superior hot distortion properties

• Excellent heat transfer capabilities

• Better shakeout properties

• Lower Hazardous Air Pollutant(HAP)and Volatile Organic Compound (VOC) emissions

• Reduction of ammonia odours

Reduce Emissions and Smoke While Maintaining Quality

You don’t have to sacrifice performance to create a better environment in-plant or in your surrounding community. TechniSand Signature Series resin-coated sands deliver the same high performance as our conventional resin-coated sands and are specifically formulated to reduce emissions, smoke and odor when producing cores and molds.

This is the first resin-coated product specifically designed to reduce free phenol emissions, and is used widely in all types of foundries. TechniSand Signature Series resin-coated sands also contain Neozien® technology, which reduces the offensive ammonia odor associated with traditional shell sand. Neozien technology ties up ammonia and leaves behind only a subtle vanilla aroma.

TechniSand Signature Series Gold

Even Lower Free Phenol, Formaldehyde, and HAPs

Our latest innovation is designed to reduce both free phenols and formaldehyde for even better in-plant air quality. And TechniSand Signature Series Gold resin-coated sands contain no ammonia-producing free hexamine, so ammonia odor is never a problem. However, Neozien technology is used in our Signature Series Gold formulations to tie up any other offensive odors that may be created during core making, mold making, casting pouring, cooling, and shakeout processes.

No matter which Signature Series resin-coated sand product you choose, you’ll create a better work environment in-plant, and in your surrounding community, while reducing emissions and improving overall air quality.

• Reduce Hazardous Air Pollutants (HAPs) by more than 41% over traditional resin- coated sand

• Reduce free formaldehyde by 35%

• Drive free phenol levels down 62%—production testing has shown free phenol actually falling below detectable limits

• Lower smoke opacity resulting from reduced emissions

• Reduce ammonia odour with Neozien technology

Note: Although the information supplied by Fairmount Minerals is believed to be accurate, it is provided without warranty of any kind. Testing has been performed by a third party laboratory. All recommendations and/or suggestions are offered for your consideration and should be investigated and verified for the applicability and suitability for your process.