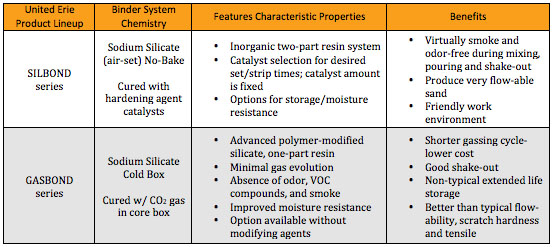

Sodium Silicate

SFP Gasbond

Gasbond Process

This process is a simple method for making foundry cores and molds quickly and economically with the use of conventional sand-handling and core making equipment. Dry sand and Gasbond binder are mixed together in a muller. On discharging, sand is rammed, jolted, or blown into a core box. Core sand is hardened by passing CO2 gas through the core. The hardened core is then ready for use without further drying or baking.

Core Sand Mix

Gasbond is a viscous liquid which mixes well with all types of core sands. Gasbond is used in amounts from 2% to 5% depending on fineness of sand, additives, and type of casting. Sand should be clay free and dry with less than 0.2% moisture. Conventional core sands are suitable. Mixing is done cold (if any additives are included with the sand mix to ease shakeout, they should be mixed with the sand before adding Gasbond). With conventional type of muller, mixing is complete in 4-5 minutes. Mixed sand is used immediately or stored in closed bins. If piled, cover with moist bags to prevent drying and air-hardening.

Making Cores

Cores are made by most any of the standard methods. Sand mix has good flowability but low green strength. With the cores that are hardened in the core box, low green strength is not important.

Gassing

Sand in the core box is hardened by introducing CO2 gas through the entire mass. For the core to harden uniformly, the CO2 gas must permeate through the whole mass. Gassing is usually complete in 10 to 30 seconds for small and medium size cores. Large cores will require gassing at several points and might take as long as several minutes. Cores made with this process are susceptible to humid conditions in storage.

Gassing equipment is manufactured by several companies which can supply information on the best methods of applying gas to cores.

Gassed cores frequently require a surface hardening agent which retards abrasion with handling. SFP’s SHURBOND is an air drying spray which builds up surface hardness fast to a point where it will match the hardness of a baked core. SHURBOND will also prevent moisture pick-up during humid months.

GASBOND is available in several grades depending on the type of metal to be cast.

Packaging

In 55 gallon drums or 20 liter pails