Refractory Paper

Introduction

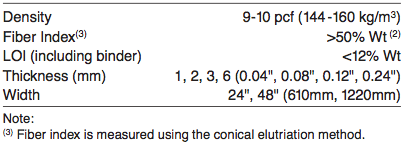

Insulfrax® Paper is an evolutionary product which is manufactured by forming Insulfrax Fiber in a nonwoven matrix. These fibers are randomly oriented during manufacturing and then held in place with a latex binder system. A specialized paper-making process is utilized to form uniform lightweight, flexible materials, including Insulfrax Paper.

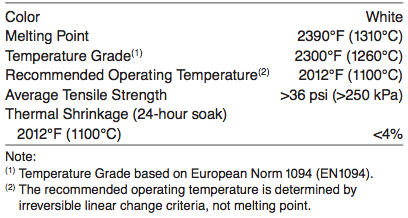

Insulfrax Fiber, utilized in Insulfrax Paper, is based upon a calcium, magnesium, silicate (CMS) chemistry. This CMS fiber chemistry has been successfully used to solve a variety of application problems from 800°F (427°C) up to 2012°F (1100°C). In addition to high temperature resistance, Insulfrax Fiber meets European regulatory requirements (Directive 97/69/EC).

The calcium, magnesium, silicate chemistry of Insulfrax Fiber provides superior wetting resistance to molten aluminum alloys. Testing with corrosive aluminum alloys at elevated temperatures has proven that Insulfrax is superior to traditional alumina/silica refractory ceramic fibers.

Insulfrax Paper will generate small amounts of smoke and trace element outgassing during initial exposure to temperatures above 450°F (232°C).

Insulfrax Paper Advantages

Insulfrax Paper offers many unique problem-solving advantages, which include:

• High-temperature stability up to 2012oF (1100°C)

• Meets European regulatory requirements

• Superior wetting resistance to molten aluminum

• Low thermal conductivity

• Flexibility

• Easy to wrap, shape, or cut

Insulating Value

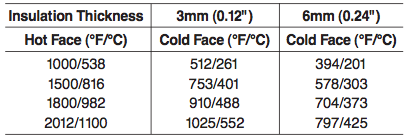

The following table summarizes the insulating characteristics of Insulfrax Paper. All heat flow calculations are based on a surface emissivity factor of 0.90, an ambient temperature of 80°F and zero mph wind velocity, unless otherwise stated.

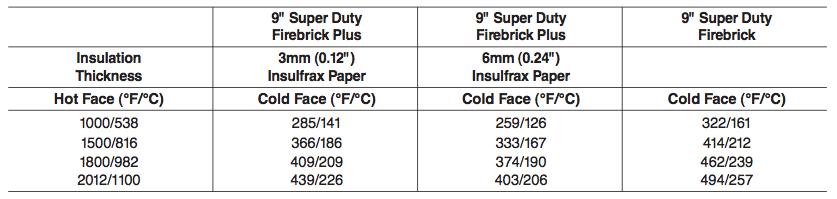

Insulfrax Paper can be used in conjunction with hard refractory materials to improve the insulating value and reduce heat loss of the lining system. The following table shows a typical application using 9″ of Super Duty Firebrick as the hot face with Insulfrax Paper as backup insulation.

Applications

Insulfrax Paper is used in many different applications, which include:

• Automotive and aerospace heat shields

• Gaskets for ovens, stoves, heaters, and other appliances

• Nonferrous ingot mold liners

• Refractory backup insulation in ladles, glass tanks, and other high-temperature furnaces

• Parting medium in brazing and soldering

• Molten aluminum transfer systems

For additional information about product performance or to identify the recommended product for your application, please contact the Unifrax Application Engineering Group at 716-278-3888.

Data shown are average results of tests conducted under standard procedures and are subject to variation. Results should not be used for specification purposes.

Health and Safety Information

Insulfrax Fiber from Unifrax, according to Directive 97/69/EC, possesses a fiber chemistry within the regulatory definition of a “man-made vitreous (silicate) fiber with random orientation with alkaline oxide and alkaline earth oxide content greater than 18% by weight.” Insulfrax Fibers have been tested pursuant to EU protocol ECB/TM/26, Revision 7, Nota Q, Directive 97/69/EC, with results that are below regulatory thresholds. As a result, Insulfrax Fibers do not require additional labeling or further testing.

Refer to the product Material Safety Data Sheet (MSDS) for recommended work practices and other product safety information.