Refractory Ropes, Braids and Wicking

Introduction

Fiberfrax® ropes, braids and wicking are a family of dense, resilient, ceramic fiber materials, widely used for a broad variety of high-temperature gasketing, packing and sealing applications. They also serve as excellent replacements for asbestos, and reduce the frequency of repairs and mainte- nance in numerous applications. Many combinations of density and construction are available.

Fiberfrax ropes, braids and wicking exhibit excellent chemical stability, resisting attack from most corrosive agents. Exceptions are hydrofluoric and phosphoric acids and concentrated alkalies. They also resist oxidation and reduction. If wet by water or steam, thermal and physical properties are completely restored upon drying. No water of hydration is present.

Fiberfrax® Rope, High Density Rope, Round and Square Braid Fiberfrax textile products are durable, high temperature, ceramic fiber packing materials that are well-suited for industrial applications. They are noted for their superior insulating and sealing ability to 1260°C (2300°F).

These materials contain approximately 20% organic carrier fiber to facilitate the carding process. The carrier fiber burns out at a low temperature with no effect on the ceramic fiber properties.

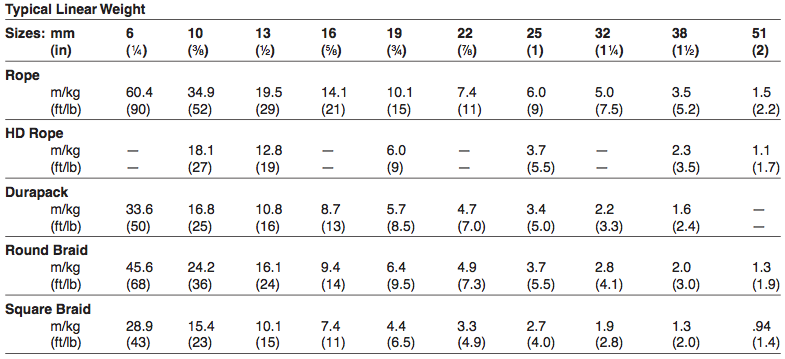

Fiberfrax ropes are twisted multi-ply ceramic fiber packing manufactured from Fiberfrax wicking. Standard minimum 3-ply rope is a low density, highly compressive product form. HD rope is up to 9-ply and provides increased compression resistance and strength and is approximately 40-65% denser than regular Fiberfrax rope.

Fiberfrax braids are used where high density and resistance to compression and mechanical abuse are required, such as in packing applications. Round and square versions are available.

Typical Applications

• Furnace door insulation and seal

• Expansion joint packing in boilers and furnaces

• Skid rail insulation

• Coke oven door jam seal

• Hot top seal

• Glass furnace tuckstone seal

• Gasket for vacuum degassing of steel during pouring

• High-temperature gasketing and packing

• Woodburning stove door seal

• Tadpole gasket bulb material

• Continuous casting starter block plug

Fiberfrax® DurapackTM Rope Packing

DurapackTM rope packing is a dense, resilient twisted cord style rope designed for packing applications that have irregu- lar surfaces or openings. This product is pliable and exhibits exceptional sealing capabilities. An inorganic surface coating provides good resistance to mechanical abuse up to 538°C (1000°F), enabling Durapack rope to be effective in high- temperature seals, packings and gaskets.

Durapack rope packing contains a small amount of organic carrier which will burn out at a low temperature with less than 3% shrinkage. It possesses the same thermal properties and chem- ical stability common to all Fiberfrax forms, resisting attack from most corrosive agents.

Typical Applications

• High temperature door seals

• Mold seals

• General maintenance in aluminum plants, foundries,refineries and power plants

• Expansion joint packing

Fiberfrax® Wicking

Fiberfrax wicking is a high temperature twisted roving made from Fiberfrax ceramic fibers and organic carrier fibers. It possesses the same thermal and chemical properties common to all Fiberfrax forms. It is typically used in applications that do not demand high tensile strength or compression resistance.

Typical Applications

• Expansion joint packing

• Gasketing on heater unit of combustion chambers

• Wick for oil burning apparatus

• Radiant tube packing for heat treat furnaces

• Packing between reinforcing bar and sleeve to prevent molten leakage

Fiberfrax® Woven Textiles

In addition to ropes, braids and wicking, the Fiberfrax textile product family also contains a variety of woven product forms. Woven textiles are composed of three basic product lines: Fiberfrax cloth, tape, and sleeving, Fibersil cloth and Flexweave 1000 cloth and tape.

The woven textile product family is a unique group of high- temperature fabrics useable in a wide variety of industrial applications. They offer superior insulating capability and exhibit excellent resistance to thermal shock, corrosive attack and breakdown due to mechanical vibration and stress.

For additional details on the available woven textile product forms, typical properties and applications for which they are appropriate, refer to Fiberfrax Woven Textiles, Product Information Sheet, Form C-1425.