Refractories Specialties Products

Introduction

The Fiberfrax® Specialties family of products includes Fiberfrax moldables, pumpables, caulks, coating cements, rigidizers, tamping mix, and Moist-PackTM blanket. Many of these products contain a wet, inorganic binder to provide both strength and hardness at elevated temperatures. The range of product forms provides a choice of materials to address a wide range of appli- cation problems, such as resistance to hot gas erosion, flame impingement, the ability to be formed into special shapes and configurations, installation into blind hot spots and hard-to- insulate areas.

Fiberfrax Specialties also possess the advantages inherent with other Fiberfrax ceramic fiber insulating materials: high tem- perature resistance, excellent insulating properties, thermal shock resistance, chemical stability, and ease of installation.

Fiberfrax Coating Cements and Rigidizers

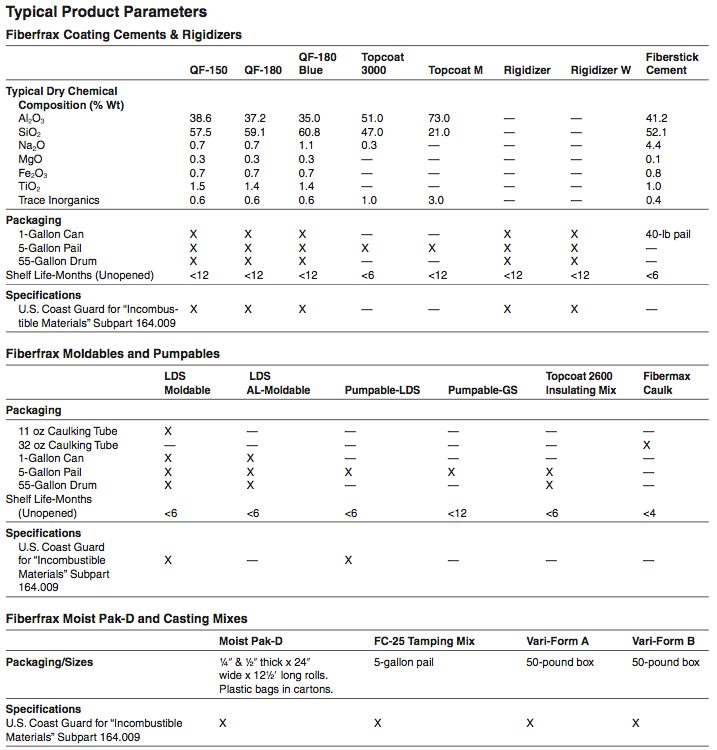

Fiberfrax QF-180TM, QF-180TM Blue, and QF-150TM coating cements provide a range of consistencies for brush, spray, and trowel-on application. These coatings have 1260°C (2300°F) temperature grade rating. They possess good adhe- sion, thermal reflectance, dielectric strength, hot gas erosion resistance, and effectively resist wetting by many nonferrous molten metals.

Fiberfrax TopcoatTM 3000 and TopcoatTM M coating cements have a temperature grade rating of 1538°C (2800°F). Topcoat 3000 consists of a blend of regular ceramic fibers and high- temperature Fibermax® polycrystalline fibers combined with an inorganic binder system. This product imparts excellent flame and hot gas erosion resistance to other product forms and effectively minimizes thermal shrinkage of fiber blankets, modules, and boards. Topcoat M is a blend of Fibermax fibers in a dry powder form which is mixed with a prescribed amount of potable water at the job site. It provides protection against slag and alkali attack when applied to Fiberfrax high-tempera- ture boards and modules.

FiberstickTM refractory cement is a high-temperature, air- setting mortar used as an adhesive to securely bond Fiberfrax Bonded modules and other product forms to refractory surfaces.

RigidizerTM and RigidizerTM W, inorganic liquid hardeners, have a temperature grade rating of 1260°C (2300°F). They are generally used to increase the durability and surface ero- sion resistance of Fiberfrax blanket and board products. Rigidizer W hardener contains an organic wetting agent to promote saturation into the substrate, whereas Rigidizer hard- ener tends to remain on the material surface of the product form to which it is applied.

Fiberfrax Moist Pak-D® and Casting Mixes

Fiberfrax Moist Pak-D is a moldable and formable blanket insulation containing an inorganic wet binder. It dries upon firing to a hard shape having a dry density of 12-18 pounds/ cubic foot. Moist Pak-D insulation possesses excellent ther- mal insulating properties and effectively resists hot gas velocities well in excess of 100 feet/second.

Moist Pak-D insulation is used primarily as a surface layer over Fiberfrax blanket linings in hot gas erosion applications (e.g., hot gas ducts, breechings, convection boxes, flares, etc.). It is also used to protect alloy hardware exposed to high temperatures, as a durable insulating cover for exhaust lines, around burner assemblies, and wherever a formable blanket is needed to provide strength and hot gas erosion resistance.

Fiberfrax FC-25 tamping mix and Vari-FormTM castable materials provide casting mixes which can be applied in small areas such as furnace access and site doors, tube sheets, and as a refractory backup.

FC-25 tamping mix is a wet mix containing Fiberfrax fibers and inorganic binders. It is poured directly from the container and tamped into place. Dry density is 20-25 pounds/cubic foot. Vari-Form is a dry mix available in two density grades of 30-40 and 50-60 pounds/cubic foot. Water is added to the dry product at the job site and mixed thoroughly. It is then simply poured and troweled into the area to be insulated. The mix sets in about 18 hours and can then be heated to operating temperature.

Typical Applications

Fiberfrax Coating Cements and Rigidizers

QF-150, QF-180, & QF-180 Blue

• Electrical insulation coatings and potting

• Adhesive for other Fiberfrax product forms

• Surface coating for other Fiberfrax product forms

• Radiant coatings for variety of substrates

• Flame-resistant coatings

• Surface coating for molten aluminum contact

• Oxidation-resistant coating for injection tubes and graphite crucibles

Topcoat 3000 & Topcoat M

• Protect high-temperature Fiberfrax lining systems from slag and alkali attack

• Improve hot gas erosion resistance of Fiberfrax high- temperature linings

• Reduce thermal shrinkage of hot face in high-temperature refractory and ceramic fiber linings

• Fill hot face surface cracks

Rigidizer & Rigidizer W

• Rigidizer for surface hardening of other Fiberfrax product forms

• Rigidizer W for saturating and rigidizing other Fiberfrax product forms

• Erosion-resistant coating for surfaces subject to high- velocity hot gases

Fiberstick Cement

• Adhesive for Fiberfrax bonded modules

Fiberfrax Moldables and Pumpables

Fiberfrax LDS and LDS-AL moldables consist of Fiberfrax ceramic fibers dispersed in a sticky water-based refractory binder. These materials have a putty-like consistency which permits application by caulking, troweling, or hand forming.

Both products adhere well to most surfaces. Drying is accom- plished at a noncritical, elevated temperature, and the resulting dried material is strong, hard, and erosion resistant. LDS-AL moldable possesses excellent resistance to wetting by many nonferrous molten metals and is used extensively in molten aluminum contact applications.

Fiberfrax Pumpable-LDS, Pumpable-GS, and Topcoat 2600 Insulating Mix were designed for application into difficult-to- reach areas requiring insulation. Fiberfrax Pumpable-LDS and Pumpable-GS have temperature grade ratings of 1260°C (2300°F). Fiberfrax Topcoat 2600 Insulating Mix has a tempera- ture grade rating of 1426°C (2600°F). A conventional air- operated extrusion pump permits application of these products directly from their container into furnace and boiler hot spots, refractory cracks, furnace door jambs, and other areas requiring high-temperature insulation and sealing.

Fibermax caulk is a high-temperature blend of Fiberfrax bulk fibers, Fibermax polycrystalline high-alumina fibers, and inorganic binder. This product is available in convenient-to- use caulking tubes. With a temperature grade rating of 1538°C (2800°F), it can be used to caulk joints and cracks in both high-temperature Fiberfrax lining systems and conven- tional refractories. Fibermax caulk is also used as a patching material around deteriorating burner blocks.

Fiberfrax Moldables and Pumpables

LDS Moldable®

• Patch refractory joints and cracks

• Hardware protection of ceramic fiber furnace linings

• Patch around burner blocks

• Refractory backup

LDS AL-Moldable®

• Lining for molten aluminum transfer troughs

• Lining for molten aluminum transfer ladles

Pumpable-LDS

• Repair and seal boiler penthouse floors

• Boiler hot spot repairs

• Refractory backup

• Backup for molten metal ladles

• Seal joints on kiln car decks

Pumpable-GS

• On-line boiler hot spot repairs

• Seal furnace door jambs

• Seal furnace penetrations

• Seal around burner blocks

• Caulk refractory cracks

• On-line refractory hot spot repairs

• Turbine exhaust duct hot spot repairs

Topcoat 2600

• Hot face repairs of ceramic fiber linings

• Sacrificial lining for areas of mechanical abuse

• Refractory lining veneer

Fibermax Caulk

• Caulk for cracks in refractory and module linings

• Patching around burner blocks

Fiberfrax Moist Pak-D & Casting Mix

Moist Pak-D

• Hot gas erosion resistant layer over Fiberfrax linings

• Recuperator linings

• External pipe insulation

• Reformer header and pigtail insulation

• Protection for process tube welds

• Process heater tube support protection

FC-25 Tamping Mix

• Furnace and boiler access door insulation

• Tube sheet insulation

Vari-Form A and B

• Backup insulation

• Ladle backup insulation

• Induction furnace insulation

• Furnace door insulation