Green Diamond

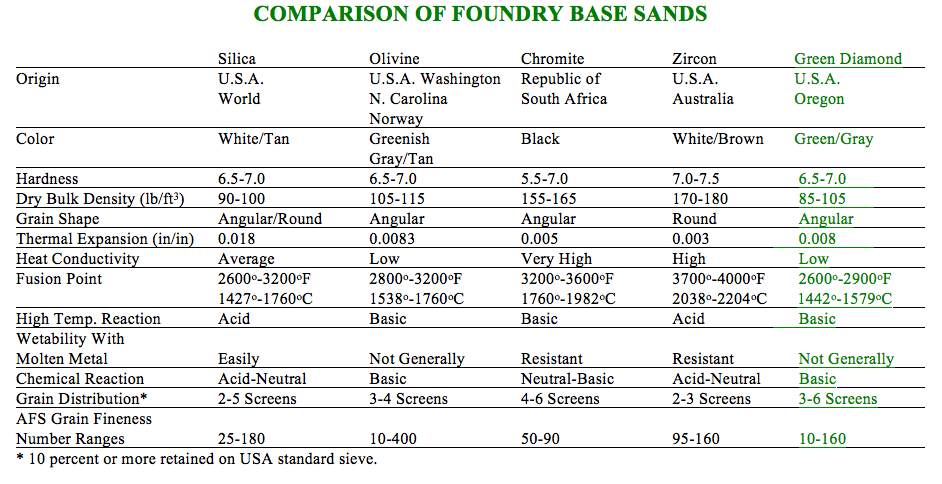

With most industries increasing their environmental consciousness we have began to see the phasing out of silica-type products and the replacement of them with new varieties that are recyclable and environmentally safe. This is where Green Diamond Sand Products has seen its niche in most industries because it is environmentally safe and is recyclable.

Green Diamond’s sands contain no free silica, eliminating the risk of respiratory silicosis, making this a product that is safe for those who handle it. Our products are also proven to be environmentally safe. This combined with its inherent properties of hardness and durability makes Green Diamond’s sand one that will not only perform well but will also treat you, your employees, and the environment in a safe healthy manner.

Green Diamond’s Ferrous and Non-Ferrous Foundry sands have low thermal conductivity resulting in less chilling than silica or olivine sands, allowing the pouring temperature to be reduced. The low thermal expansion reduces the need for cushioning additives or combustibles. It is a tough grain that breaks down very little in use and is environmentally friendly. A wide range of screen distributions are available. Starting in 2003 Green Diamond Sand Products now has the ability to pre mull our sand with clay additives for specific customer requirements.

Green Diamond Foundry Sands:

• Contain no free silica, eliminating the risk of silicosis.

• Approved to be environmentally safe.

• Makes more molds and cores per ton of sand, also cutting disposal amounts and costs by as much as 20%.

• Durability is greater than both Olivine and Western silica sands, meaning less breakdown reducing dust and the need for system make up.

• Less chill, pour colder.

• Low thermal expansion.

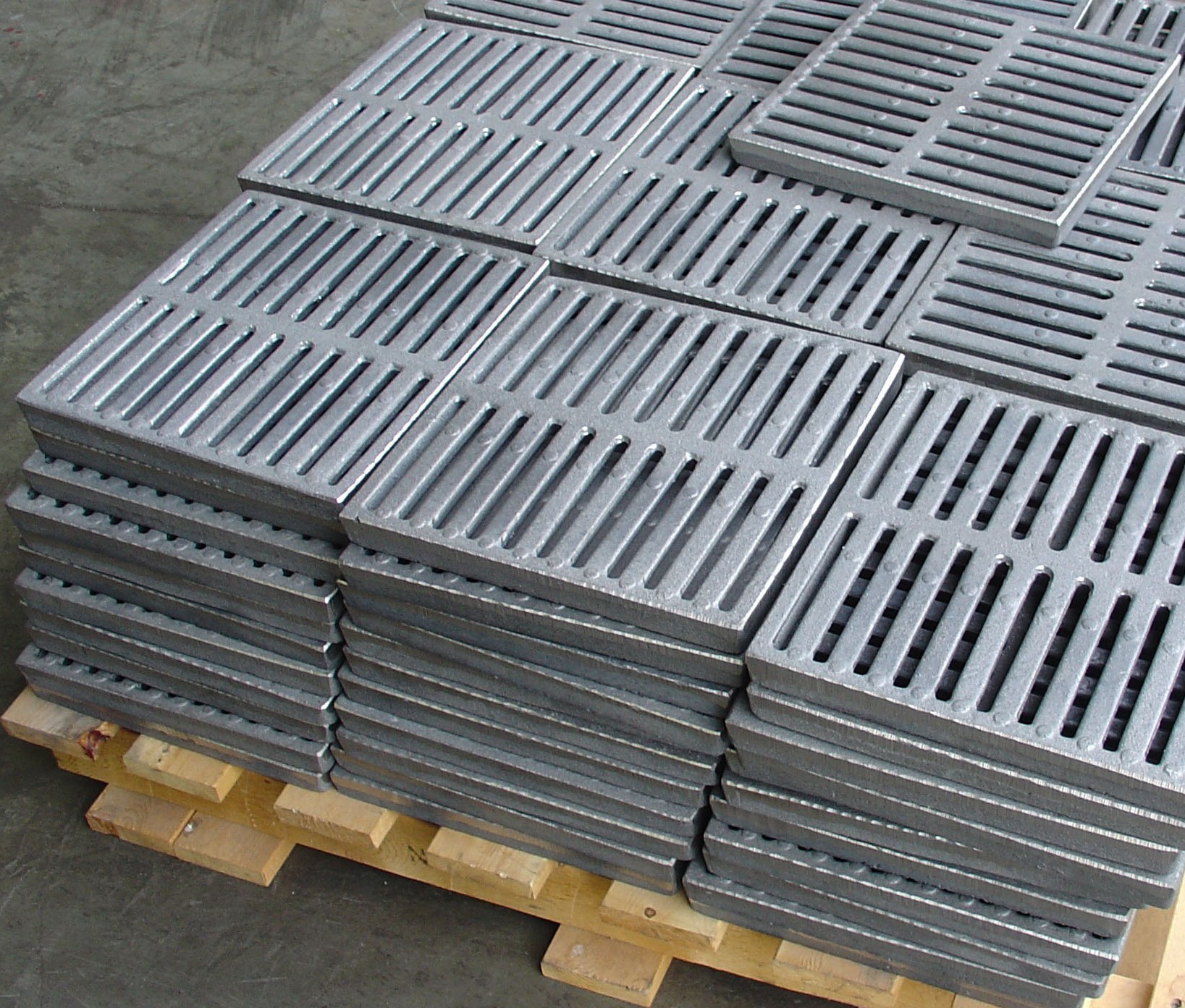

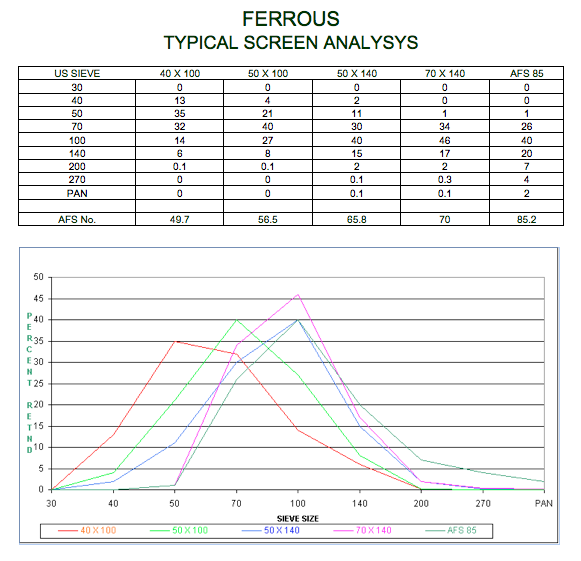

Ferrous Foundry Sands:

Sizes and blends for castings and molding with manganese steel, gray, ductile and wear resistant irons.

40 x 100 (50 AFS) – Heavy manganese steel and iron.

50 x 100 (57 AFS) – Heavy manganese steel and iron.

50 x 140 (66 AFS) – Heavy manganese steel and iron.

70 x 140 (70 AFS) – Medium to light manganese steel and iron.

• Blends- Contact us for product sizing and blending recommendations.

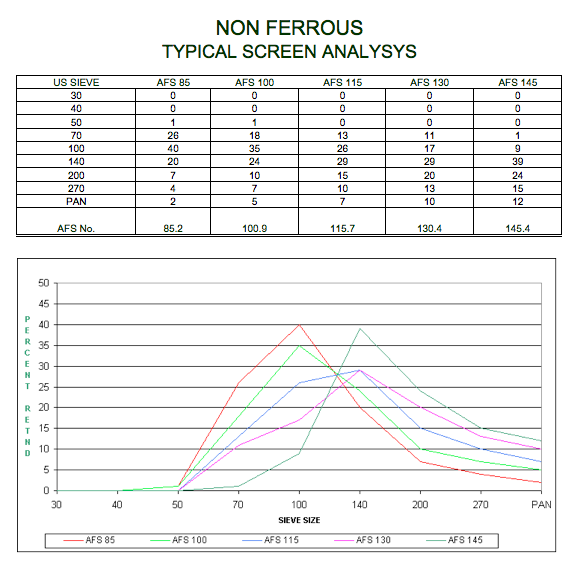

Non-Ferrous Foundry Sands:

Sizes and blends for castings and molding in the iron, brass, bronze, and aluminum foundry industry.

70 x 140 (70 AFS) – Cores and light iron.

AFS 100 -Aluminum, cores, and light iron.

AFS 115 – Aluminum, brass, and bronze.

AFS 130 – High detail.

140 x 270 – For blending with 70 x 140.

• Blends- Contact us for product sizing and blending recommendations.