Bentonites

(Southern – Calcium)

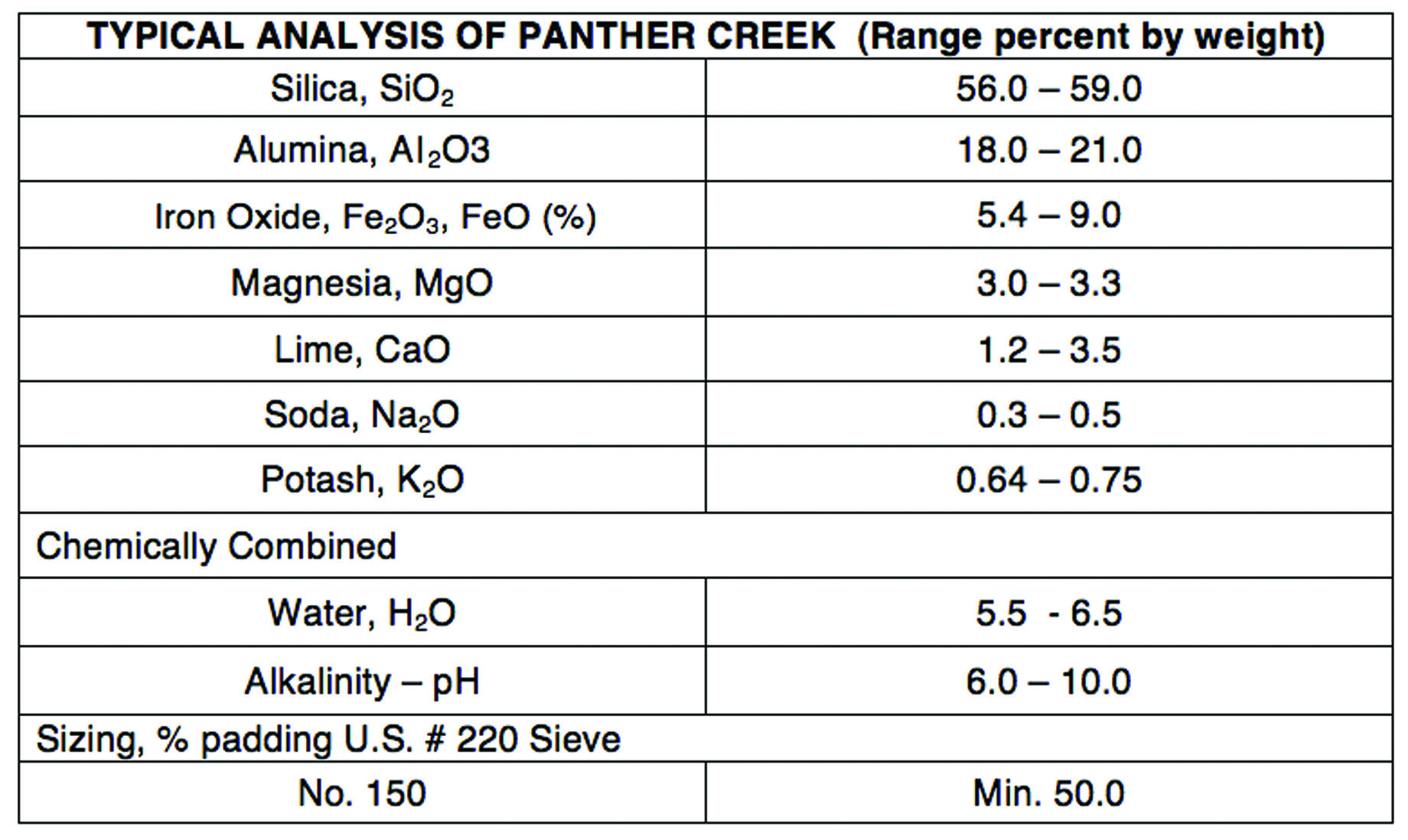

Calcium Bentonite is produced from a unique Mississippi clay deposit with a cationic exchange capacity ideally suited for the rigors of metal casting. It is more responsive to moisture, develops faster and retains better molding characteristics over a wider moisture operating range.

For foundries seeking improved mold density and dimensional control, Calcium Bentonite can deliver un to 25% greater green compression strength. Southern Bentonite’s compaction and adhesive properties also improve mold permeability, making it the ideal clay for foundrymen seeking improved surface finish with finer molding sands. Despite repeated exposure to high temperatures, it will remain durable and active, producing high methylene blue results and requiring less additions in reuse.

Our Southern Bentonite enhances the production of detailed, intricate castings produced in gray iron, ductile iron, malleable iron and nonferrous alloys. It is an excellent choice in either jobbing or high production operations.

BENEFITS

– Excellent Shakeout

– Excellent Ramming Characteristics

– Excellent Flowability

– High Green Compression Strength

– Low Dry and Hot Compression Strength

– Consistent Quality

(Western – Sodium)

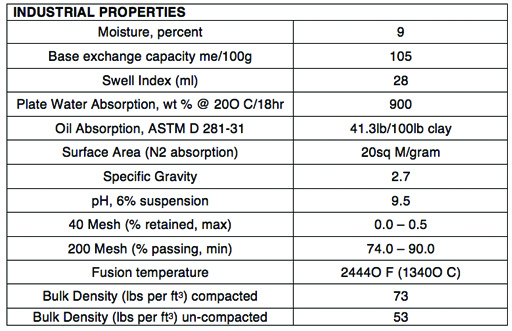

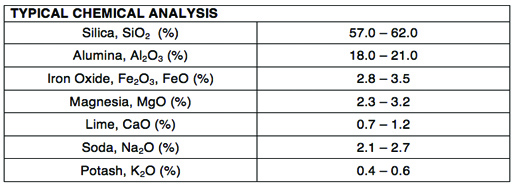

Standard Bentonite Industrial Grade – 200 Mesh Western Bentonite began as volcanic ash millions of years ago. After weathering from rains and pressure by megatons of seawater, volcanic ash was transformed into what we know today as Sodium Bentonite.

Western Bentonite is the preferred binder for production of green sand iron and steel castings. It is also selected in the production of copper base and aluminum castings when extra performance is needed. Because it is more durable than other bonding materials, Western Bentonite requires less replacement when sand mixtures are re-bonded. Western Bentonite bonded sand mixtures offer high dry compression strength and high hot compression strength to prevent sand erosion, cuts, washes, inclusions, burn-on and scabs.

Molding sand practice is based on having low clay content coupled with low temper water. Western Bentonite meets these parameters. It imparts excellent dried and fired strengths to molding sand where high temperature pouring occurs. Western Bentonite’s unique capability to hold water prevents mold surface erosion by molten metal. It also provides excellent strength and toughness to molding sand mixtures, enabling good draw of the pattern.

BENEFITS

– Provides Highest Tensile Properties

– Combats Friability

– Excellent Dry and Hot Properties

– Increases Durability and Toughness

– Controls Expansion Problems

– Quick Green Compression Strength Development

– High, Quick Dry Compression Strength

– Intermediate Hot Strength

– Low Viscosity