Chromite

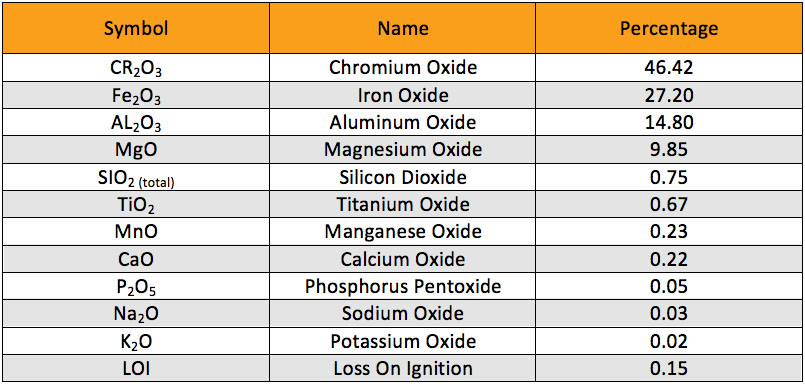

We offer a superior quality chromite sand for the steel, foundry and refractory industries. At all stages of our supply process, stringent quality control measures are employed to assure that this critical mineral is on target with specification.

Chromite, as is indicated by its early crystallization, is resistant to the altering affects of high temperature and pressures. These characteristics explain the use of chromite as a heat conductive foundry molding sand, which allows localized or general chilling of castings to improve their integrity.

Advantages of Chromite

- high quality

- good for chilling casting

- prevent hot tears

Typical Uses

- used to harden steel, to manufacture stainless steel and to form alloys

- used in plating to produce a hard, beautiful surface and to prevent corrosion

- used by the aircraft and other industries for anodizing aluminum

- the refractory industry uses chromite for forming molds and shapes, as it has a high melting point, moderate thermal expansion, and stable crystalline structure

Colour shiny black

Specific Gravity 4.4

Bulk Density (loose) 163 lb/ft³

Bulk Density (compacted) 181 lb/ft³

Grain Shape Sub-angular

Melting Point (°F) 3350 – 4000

Melting Point (°C) 1850 – 2200

Solubility Negligible

Packaging

- 50 lb paper bags, 100 lb paper bags

- 3000 lb super sacs

- bulk (blower truck or rail hopper cars)