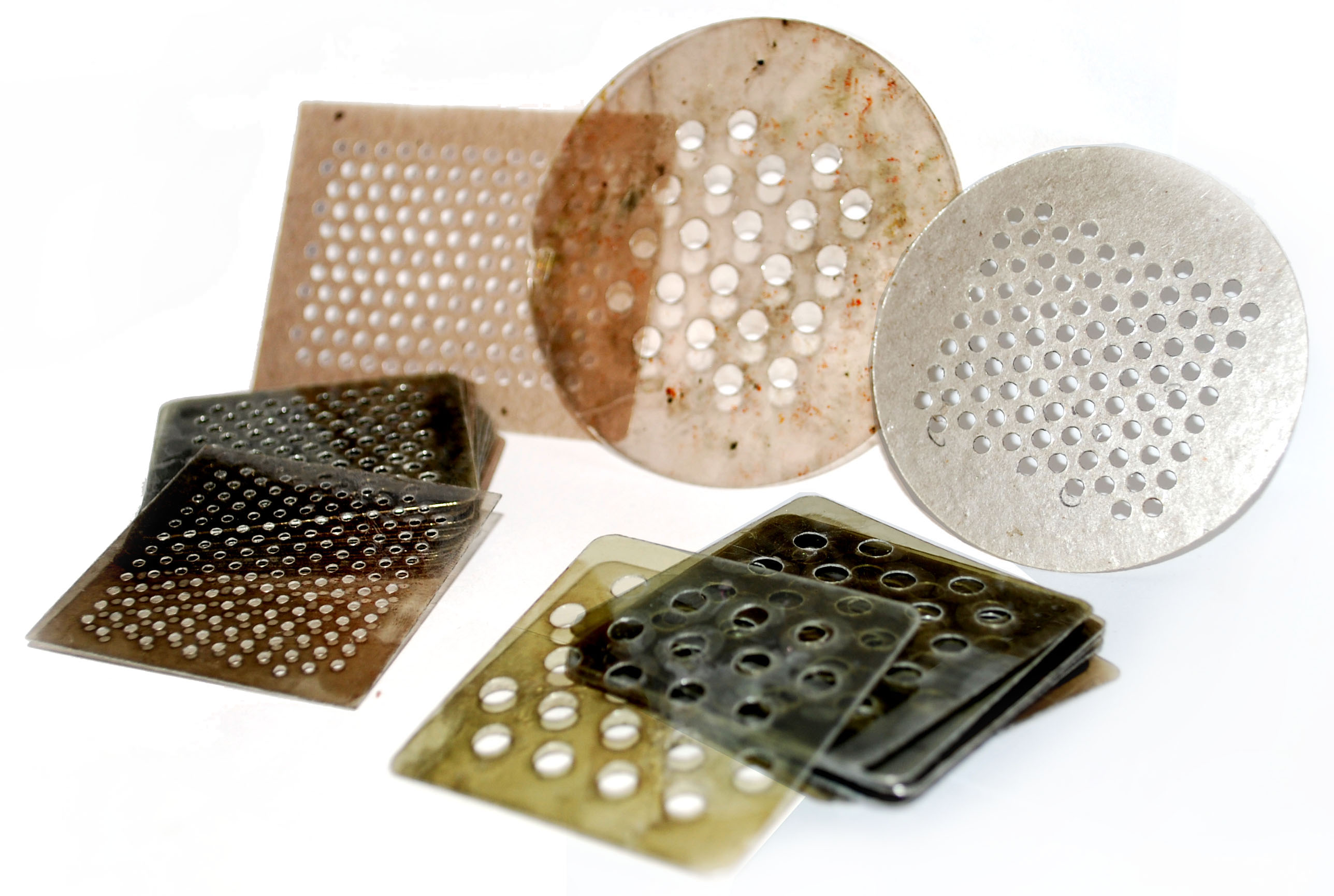

Mica Strainers

Mica Strainer Cores are suitably used by metal casting foundries for brass, bronze, and aluminum sand castings as well as for some smaller ferrous castings to catch impurities and control the pour rate. They act as both a choke and a strainer during pour, eliminating gating costs, dross, contamination, and reducing polishing belt costs – all while producing a better and brighter casting.

They can be placed over the sprue hole with no recess needed. They also provide easy access to skim off with 100% metal recovery in the re-melt. The mica strainer cores are a thin, inorganic, non-contaminating, non-moisture absorbent, material which provide easy handling and storing. Some of the popular shapes and sizes of mica strainer cores in the foundry are:

Size Number of Holes Thickness

1½” x 1½”

2″ x 2″ 22, 93, & 148 .004″ – .008″

1 ½” x 2″ 88 .006″ – .010″

2 ½” x 2″ 93 .008″ – .012″

2 1/4″ x 3″ 140 .014″ – .018″

3″ x 3″ 22

2″ dia 22 & 93

2 ½” dia 22 & 93

The process is clean and simple.. the results are a low cost, quality strainer that is perfect in most non-ferrous metal filtrations applications.