Filter Cloth (aluminum)

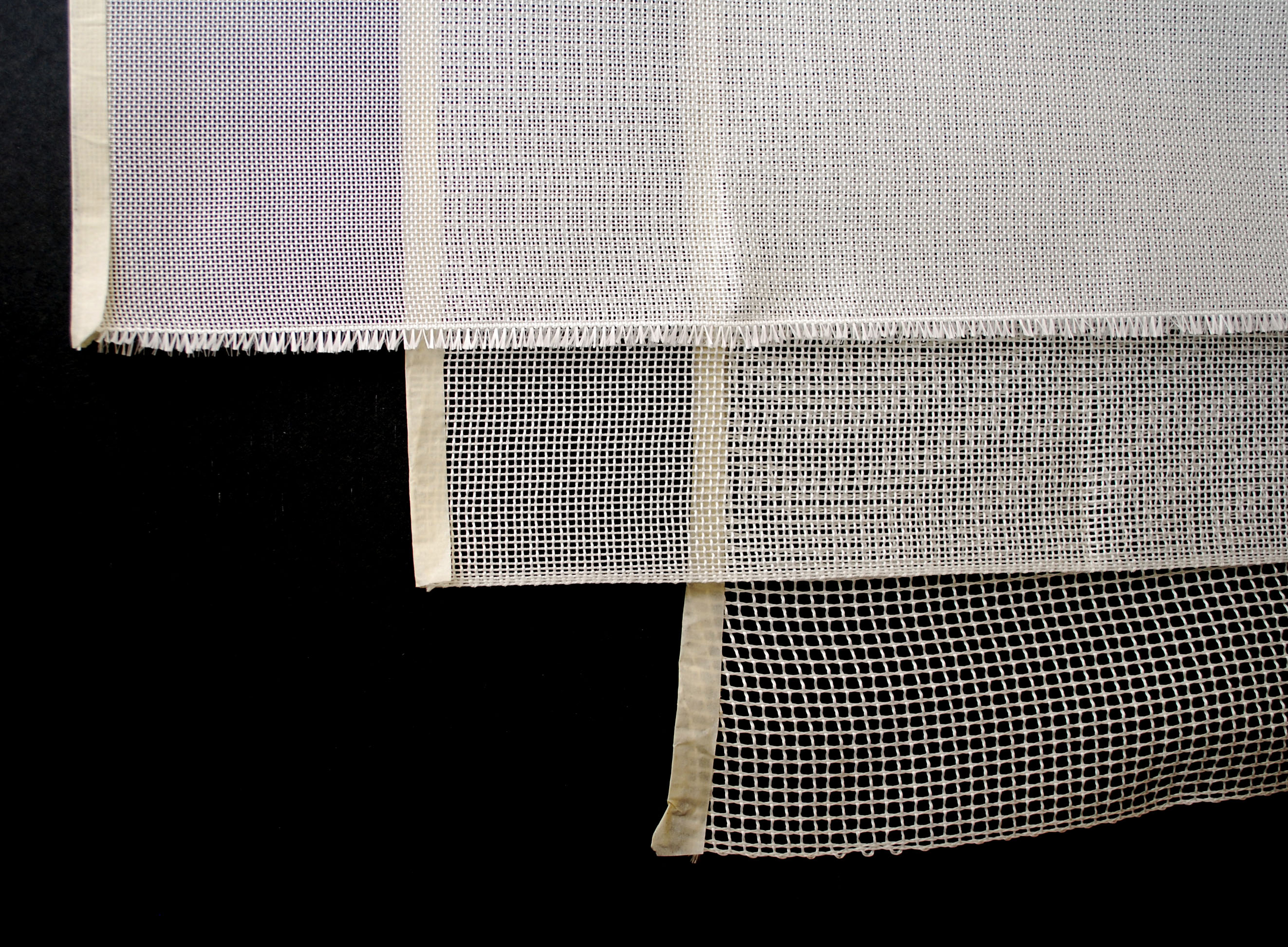

Filter Cloth for Aluminum Fiberglass cloth is an inexpensive and effective method of non-ferrous molten metal distribution and filtration available in a variety of styles. Plain Weave is a simple weave where the warp yarns run over and under the fill yarns

Twill Weave cosists of the warp yarns running over two or more fill yarns

Leno Weave style interlocks the warp yarns, which cross over eachotherand join together with the fill yarns

(Also, three, four, and six strand cloths are available)

Our filter cloth is woven to specification on approximately 100 linear yard rolls. Standard widths are obtainable for each style. Minimum orders may apply on some widths. Standard or brown finishes are available.

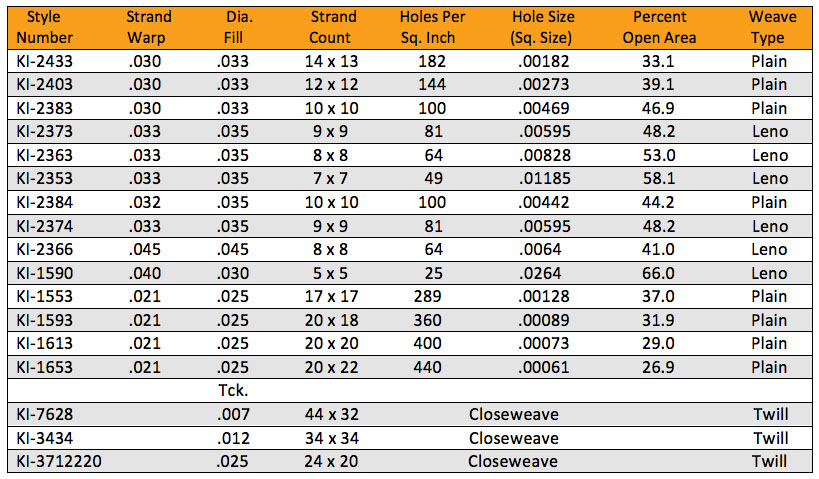

Specifications for Aluminum Distribution and Filtration

Vacuum formed shapes are produced by dewatering a slurry of Fiberfrax Bulk Ceramic Fibers and special high temperature binders. This manufacturing method permits considerable freedom to vary shape, thickness, density and hardness. Often the vacuum casting technique provides the most economical answer to producing large quantities of parts in simple or complex configurations.

Advantages of Vacuum Formed Shapes

• High temperature stability

• Low thermal conductivity

• Low heat storage

• Lightweight

• Thermal shock resistant

• High heat reflectance

• Excellent corrosion resistance

Chemical Properties

Our vacuum formed shapes resist attack from the most corrosive agents. Exceptions are hydrofluoric and phosphoric acids and concentrated alkalies. Vacuum cast parts also resist oxidation and reduction. If wet by water or steam, thermal and physical properties are completely restored upon drying. No water of hydration is present.

Typical Physical Properties

Colour

Basic Composition

Continuous Use Limit

Melting Point

Density Range

Thickness Range

Specific Heat 1093°C (2000°F)

Off-White

Alumina-Silica

1260°C (2300°F)

1790°C (3260°F)

190-640 kg/m³ (12-40 lb/ft³)

3.2 mm (1/8″) up

1130j/kg³ C (.27btu/lb F)