Filter Cloth (ferrous)

Flexsil

Product Description

FLEXSIL® refractory cloth filters are designed to extract dross, slag, refractory particles, and non-metallic inclusions from molten metals. FLEXSIL filters were developed as a low cost, high efficiency alternative to cellular ceramic and reticulated ceramic foam filtration systems. Made from specially treated silica fibers, FLEXSIL filters are capable of withstanding pouring temperatures ranging up to 3000°F (1620°C). FLEXSIL filters are ideal for in-mold filtration of gray, malleable, white, compacted graphite, and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys. FLEXSIL filters are available in a choice of mesh sizes, and can be cut or formed to virtually any desired size or shape. FLEXSIL cloth is also available in 25- or 50- yard rolls.

Chemically Active Filter Surface

Chemically Active Filter Surface

FLEXSIL silica cloth filters trap impurities using a method uniquely different than that of mullite or alumina filters. When molten ferrous metal contacts a FLEXSIL filter, special surface coatings decompose to instantly form a continuous film of fayalite (2Feo.SiO2). The fayalite coating becomes soft and viscous at high temperatures to entrap inclusions that come into contact with it. The resulting sticky film enables even micron-size inclusions to be filtered out of the very first metal to pass through the filter. In magnesium treated ductile iron filtration, the fayalite coating absorbs magnesium reaction products contained in the molten metal. Low melting solid solutions are formed on the surface of the silica fibers to help remove inclusions, especially magnesium dross, sulfides, and silicates formed by the nodularizing treatment. Conventional hard-fired ceramic filters composed of alumina or mullite cannot capture inclusions in this way because alumina and mullite do not form a fayalite coating. FLEXSIL filters are especially effective in removing fluid slags, such as manganese silicates, from cast iron.

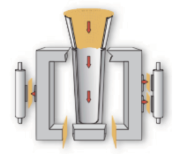

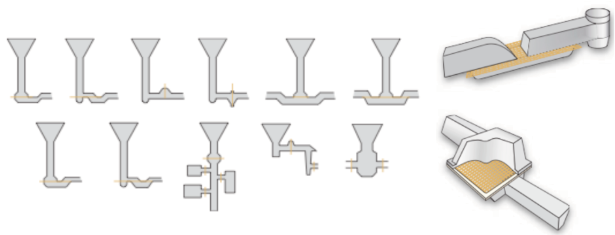

Typical Flexsil Placements

Other Applications

De-Risering and Runner Segmentation Cut sections and core sand-reinforced filter cloth can be placed across casting and riser in-gates for filtration and shake out de-risering. Small sections of FLEXSIL may also be placed directly into ports in cores to achieve filtration and knock-off. De-risering of ductile iron castings may be easily accomplished using FLEXSIL containing cores on casting with top risers. Savings of 50% or more can be realized through riser removal.

Multiple Crossover Applications

FLEXSIL filters can be positioned across down-sprues, and horizontally or vertically across runners for single or multiple filtration. A single strip of FLEXSIL can provide multiple filtration by a “down” then “up” flow pattern. This arrangement produces the cleanest metal at the lowest cost.