Chaplets

Double Head Chaplets are manufactured using mild steel, generally coated with tin and used when casting a heavy metal section where the increased strength resulting from welding the chaplets is required. Non-ferrous metal such as stainless steel are available upon request. The information listed in the chart details general characteristics on their dimensional design. These chaplets can have grooved or plain stems, perforations pierced in the plates, extensions or pins welded which protrude from the plates. The plate(s) can be curved to a specific radius. Additional design modifications can be integrated to meet your specifications. Height can be produced from 1/4″-5,7 to 5″-127,0.Double Head

Triple Head Chaplets can be manufactured in a variety of ways and in a range of metals. They are used in castings where two headed chaplets do not knit or fuse, creating a defect in the casting, usually porosity. By adding a third plate know as the center dam into the design of the chaplet, this feature can eliminate the defect in the casting. Pending your application we can best match the appropriate manufacturing process to suit your specifications. Because of the various manufacturing processes these chaplets can have grooved or plain stems, perforations pierced in the plates, or extensions or pins riveted or welded which protrude from the plates. Center dams can be larger or smaller than the outside plates. They can have serrations or smooth edges. Additional design modifications can be integrated to meet your specifications. Creating a Triple Head Chaplet for your specification is based on the application required. Pressure Tight (Triple Head)

Motor Chaplets are manufactured from mild steel, generally coated with tin and used in thin-walled casting. Non-Ferrous metals such as aluminum, copper, and stainless steel are available upon request. The information listed in the chart details general characteristics on their dimensional design. These chaplets can have grooved or plain stems. Perforations pierced in the plates. Extensions or pins riveted or welded which protrude from the plates. The plate(s) can be curved to a specific radius. Additional design modifications can be integrated to meet your specifications. Height can be produced from 3/16″-4,5 to 3″-76,2. Motor Chaplets

Perforated Chaplets are manufactured from tin coated steel sheet or non-ferrous sheet, depending on the metal being cast. They can be used in thin-walled or heavy metal sections of castings, but are best suited for placing in the bottom or drag of the mold. Standard perforation is #6 (.075 hole on .125 center). Standard material thickness is .015. For special applications, the size of perforation holes, the perforation pattern, and thickness of material can be modified to meet your specifications. These chaplets can be produced to resemble a box, Form #1 and 1A, with curvatures, Form #4 and 4A, to resemble a wedge, Form #7 and 7A, or to clip onto cores, Form #8 and 8C. The information listed in the chart details general characteristics on their dimensional design. Perforated Bridge

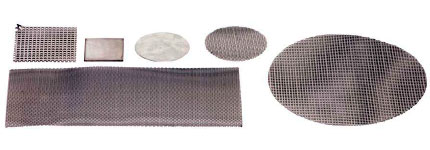

Skim Gates are manufactured using tin-coated steel sheet or non-ferrous sheet, depending on the metal being cast. Standard perforation is #6 (.075″ hole on .125″ centers). Standard material thickness is .015″. For special applications, the size of perforation holes, the perforation pattern, and thickness of material can be modified to meet your specifications. They are used to control the flow of metal and remove impurities as molten metal enters the mold. Core Plates are manufactured using mild steel, usually 1″ (25,4 MM) or smaller. These are generally tinned and used in the gating system to restrict the flow of metal, or to create larger bearing surface for chaplets against cores or molds. Because of their application(s), no standard material thickness applies. It is determined based on your specifications. The information listed in the chart details general characteristics of dimensional design for Skim Gates and Core Plates.Perforated Tin Plate

Preglued Chaplets are Motor Chaplets, Triple Head Chaplets, or Double HeadChaplets with a thin uniform layer of glue applied to one head of the chaplet and symmetrically placed on release paper. Because they are ready to be placed in the mold or on a core, increased efficiencies are achieved. In addition, the uniform layer of glue eliminates variability of glue thickness and reduces excess gas formation. Inventory control is achieved by each sheet having a fixed number of chaplets.Pre-Glued

Radiator Chaplets are manufactured from mild steel, generally coated with tin and used in thin-walled castings where the chaplet can be set in the pattern or into an insert in the pattern before the mold is formed or rammed. Non-ferrous metals for the stem such as aluminum, and copper, are available upon request. The information listed in the chart details general characteristics on their dimensional design. These chaplets can have knitting nicks, to aid in fusion, on the stems and a break-off nick above the shoulder. Their heads can be produced in a cross, square, or “SR” open configuration. Additional design modifications can be integrated to meet your specifications. Length of the stem can be produced from 1/2″-12,7 MM to 3-1/2″-88,9 MM Radiator

Hinge Tubes are made out of tin coated steel packed with resin coated sand and are used to create holes through ribs and lugs which extend perpendicular to the parting line. The sand packed inside the tube to create the hole in the casting is knocked out during shakeout. They offer the means to create dimensionally accurate holes for pins or bolts and eliminate the need to drill holes.Hinge Tubes