Core and Mold Washes

Shurcoat ZA-95

• SFP SHURCOAT ZA-95 is a high refractory zircon based alcohol coating, it lends itself both to cores and molds and assures good consistent blending.

• SHURCOAT ZA-95 is recommended when a protective barrier is required to prevent or minimize metal penetration into the sand. It promotes excellent casting surface finish in high temperature conditions.

• SHURCOAT ZA-95 can be utilized with steel, gray iron, malleable iron, ductile iron, copper base alloys and in aluminum casting where a chill effect is desired.

• SHURCOAT ZA-95 can be air dried. To speed drying the coating can be ignited or oven dried.

Recommended Baumé

For spraying 55º- 65º

For brushing 80º – 85º

For swabbing 80º – 85º

For dipping 55º – 60º

Use three parts of SHURCOAT ZA-95 and one part of IPA (isopropyl alcohol) to reduce the coating to approximately 60º Baumé.

Application

SHURCOAT ZA-95 can be applied to green sand molds, all known chemically bonded sands, hot resin systems and sodium silicate systems.

Note: On chemically bonded systems a “when to wash” should be observed. The general rule is to apply the coating after the surface has been completely cured. Since the actual waiting time before applying a coating varies, depending upon the conditions. Example, if the strip time is five minutes then it is suggested to wait another five minutes before the coating is applied.

Recommendation

Agitation prior to use may be necessary.

Packaging

45 gallon steel drums (approx. 850 # net) or 5 gallon pails (approx. 65 # net)

Shurcoat GA-100

Shurcoat GA-100 is a premium graphite coating formulated for use on cores, molds, or chills. As a graphitic coating it will exhibit excellent resistance to burn-in, excellent peel for iron and non-ferrous castings and good separation of chills from the casting surface.

Application

• Shurcoat GA-100 can be used alone or as a topcoat over zircon or other refractory coating bases to provide for extra burn-in resistance. This product can be sprayed, brushed, or swabbed.

• If Shurcoat GA-100 is applied to chills they should be clean and dry before applying this coating.

• Shurcoat GA-100 can also be used under other coatings in hot spots or trouble areas as a supplement. The following chemical and physical properties are provided as reference only. The chemical data is an approximate analysis based on formula weights, test results, and supplier data.

Chemical Properties

Component Weight Percent

Carrier 50 – 55

Carbonaceous Refractory Solids 25 – 35

Silicate Refractory Solids 10 – 20

Binding, Suspending and Flow Modification Agents 4 – 10

Physical Properties (as produced)

Apparent density (S.G.) 1.00 – 1.20 g/cm3

Baumé 40º – 50º

Viscosity 200 – 700 cP

General Use Information

• Shurcoat GA-100 is supplied as a premix that can be diluted with anhydrous Isopropanol (isopropyl alcohol or SFP THINNERS) to the desired viscosity or Baumé. In some application Methanol or Ethanol may also be used as a diluent. However, the dilution ratio and coating properties in use will be a bit different. As used, Baumé is directly related to your production requirements. The optimum Baumé or viscosity can be determined through trial with consideration given to casting properties, surface conditions, drying considerations, and other variables

• Shurcoat GA-100 can be air dried or lit-off depending upon the application and on your time and space constraints. As with any other coating line it is recommended to follow the supplier information for determining Baumé.

Packaging

45-gallon steel drums (approximately 450 pounds net), 5-gallon metal pails (approximately 40 pounds net)

Shurcoat GA-300

Product Description

• Shurcoat GA-300 is an alcohol slurry blend of zircon flour and flake graphite. Shurcoat GA-300 lends itself very practically in foundry applications by reducing time and assuring good blending characteristics.

• Shurcoat GA-300 means better castings, provides cores and molds with a highly refractive coating with excellent sand peel from castings, and creates an impermeable barrier between the sand surface and molten metal which results in an improved casting finish.

• Shurcoat GA-300 can be utilized with non-ferrous metals (aluminum, brass and bronze), gray, ductile and malleable iron.

• Shurcoat GA-300 can be air dried. To facilitate drying, the coating can be ignited or even dried

Recommended Baumé

For Spraying 35º – 50º

For Brushing 70º – 85º

For Swabbing 40º – 50º

For Dipping 28º – 35º

General Use Information

• Three (3) parts of Shurcoat GA-300 to One (1) part of alcohol (isopropyl alcohol or SFP THINNERS) by volume will produce approximately 50º Baumé.

• 1½ parts of Shurcoat GA-300 to One (1) part of alcohol (isopropyl alcohol or SFP THINNERS) by volume will produce approximately 28º Baumé.

• Shurcoat GA-300 can be applied to green sand molds, all known chemically bonded and hot resin systems. Also recommended for use with (CO2) sodium silicate systems.

• On chemically bonded systems, a “when to wash” should be observed. The general rule is to apply the coating after the surface has been cured. Since the actual waiting time before spraying a coating varies, depending upon the conditions, it is suggested that if normal operation includes a five-minute strip, then wait another five minutes before coating.

Recommendation

Agitation prior to use may be necessary.

Packaging

45-gallon steel drums (approximately 660 pounds net) 5-gallon metal pails (approximately 60 pounds net)

SphereCoat

SphereCoat is an advanced ceramic composite coating made of specifically for the foundry industry. It prevents molten metal from penetrating into the grains of sand in the core and mold materials. SphereCoat ensures that the sand casting surface remains smooth and heat resistant. SphereCoat prevents erosion of cores and molds during filling and prevents the molten metal from reacting with the molds materials. The overall result is a casting surface free of cracks, penetration, gas, burn-in etc.

SphereCoat can be used with many types of metals such as iron, steel, aluminum and copper based alloys. Because SphereCoat has been engineered from a ceramic composite, there is little to no reaction with specialty metals such as manganese steel.

SphereCoat creates a protective barrier layer with an adequate level of thickness to prevent any contact between the molten metal and mold material. The level of thickness needed will vary depending on the thickness at the wall area, ferro-static pressure, and pouring temperature.

Physical Properties

Appearance: Red Slurry

Baumé as Shipped: 85º – 90º

Density: Approximately 13lbs/gallon

Solids Level: 76%-78%

Flash Point: 11.7ºC (open cup) 13ºC (closed cup) alcohol based

SphereCoat should be mixed thoroughly before application. Explosion-proof, motor-driven mixers are recommended with alcohol-based coatings such as SphereCoat. SphereCoat is typically shipped as a heavy slurry produced to approximately 85º – 88º Baumé, but can be shipped at requested Baumé. If necessary, the Baumé can be reduced by reducing the SphereCoat with Isopropyl Alcohol (IPA 99%). IPA is highly flammable and caution must be exercised with use.

Appearance: Red Slurry

Baumé as Shipped: 85º – 90º

Density: Approximately 13lbs/gallon

Solids Level: 76%-78%

Flash Point: N/A

SphereCoat Application and Use Instructions:

SphereCoat should be mixed thoroughly before application. SphereCoat is typically shipped as a heavy slurry produced to approximately 85º – 90º Baumé, but can be shipped at requested Baumé. If necessary, the Baumé can be reduced by reducing the SphereCoat with water.

Nolite SGS Premix

Product Description

SFP Nolite SGS is concentrated slurry consisting of a blend of Aluminum Silicates and Graphite. This product is designed for dipping and flow coating applications. Under certain conditions this product may also be applied by spraying. The relatively low density of the refractory materials along with a unique combination of flow modification materials produce a coating that builds up well on both horizontal and vertical surfaces. The refractory blend is highly insulating and resistant to burn-in and veining on cores and molds. The sintering point of this product makes it suitable for use in light to medium section iron, aluminum, and other non-ferrous casting processes.

Application

SFP Nolite SGS may be diluted with water as required to optimize the application process. This product should be re-mixed thoroughly before use to ensure uniformity in the drum or pail. As with any foundry core and mold coating, the application process and properties will depend on considerations such as pattern size, casting type, section thickness, and application equipment. The optimum method may be determined with Smelko Foundry Products personnel’s assistance through trial.

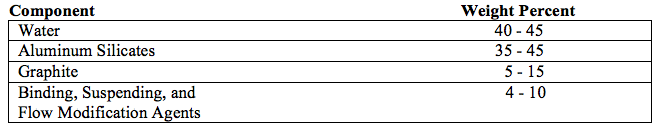

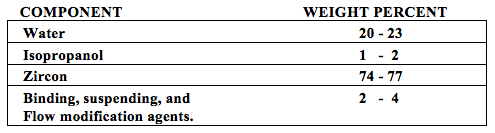

The following chemical and physical properties are provided as reference only. The chemical data is an approximate analysis based on formula weights, test results, and supplier data.

Packaging

Nolite SGS is supplied in 635 – pound steel drums or 60 – pound pails. Other consistencies or package types may be supplied when practical.

High Resist ZS

Product Description

SFP HI-RESIST ZS is a high solids zircon/water core and mold coating for use in spraying, brushing, and swabbing application. The refractory solids contained in this product along with its application properties make it suitable for use in a wide range of applications including medium to very heavy section steel, iron and non-ferrous castings.

Application

SFP HI-RESIST ZS is supplied in 1000-pound steel drums or 90-pound poly pails. This product may be used as-is, but is more likely to be used when diluted with water, as required, to optimize the application properties. This product should be re-mixed thoroughly before use to ensure uniformity in the drum or pail. As with any foundry core and mold coating, the application process and properties will depend on considerations such as pattern size, casting type, section thickness, and application method/equipment. The optimum method may be determined with the assistance of your salesperson, through trial.

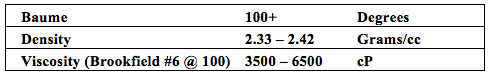

The following chemical and physical properties are provided as reference only. The chemical data is an approximate analysis based on formula weights, test results, and supplier data.

Chemical Properties

Physical Properties (as produced)