Insulating Blanket

Introduction

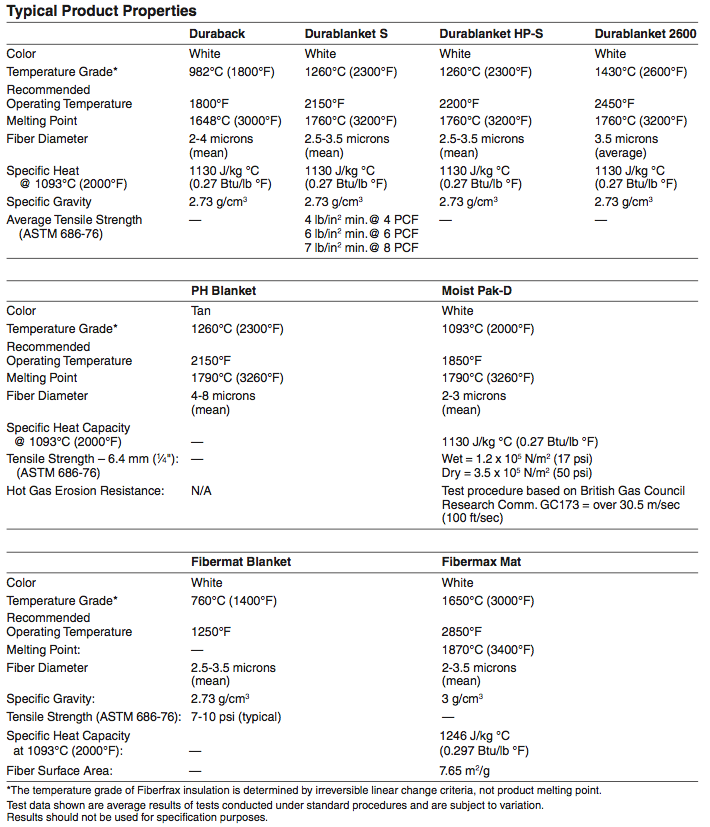

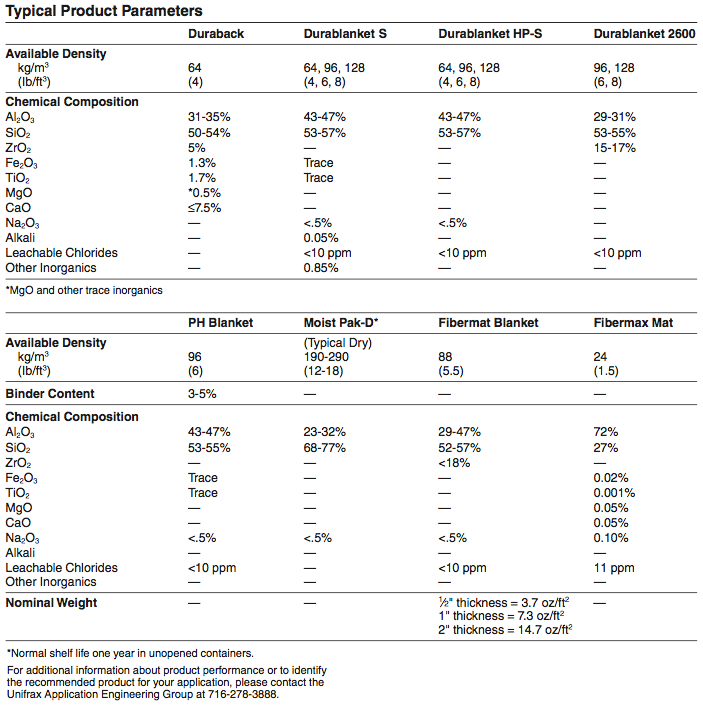

The Fiberfrax® blanket and mat product family is a group of lightweight, thermally efficient ceramic fiber insulating materials that combine the advantages of dimensional stability at high temperatures with complete resistance to thermal shock. Featuring a broad range of thermal capabilities and physical characteristics, this product family provides proven and effective solutions to a variety of heat processing applications.

Durablanket® ceramic fiber products are high strength, needled insulating blankets that are made from spun Fiberfrax ceramic fibers. The extra-long spun fibers, cross- locked through a unique forming process, produce a blanket with exceptional handling strength. The Durablanket product family is completely inorganic and available in a variety of temperature grades, densities, and sizes.

Fibermat® Mat, PH blanket, and Moist Pak-D® insulation provide additional options for specific application requirements ranging from high-temperature filtration to hot gas velocity resistance.

Fibermax® Mat is a high-temperature, flexible mat product entirely composed of Fibermax polycrystalline mullite fibers, making it an extremely lightweight, highly resilient insulator that is virtually free of unfiberized (“shot”) particles.

Having excellent chemical stability, Fiberfrax blanket and mat products are unaffected by most chemicals except hydrofluoric and phosphoric acids and concentrated alkalies. If wet by water or steam, thermal and physical properties remain unaffected after drying.

Durablanket® S

Fiberfrax Durablanket S insulation is a strong, lightweight, flexible needled blanket that is made from spun ceramic fibers. Available in a wide variety of thicknesses, widths and densities, Durablanket S insulation provides an array of proven solutions for a broad spectrum of application problems.

Duraback®

Fiberfrax Duraback blanket is a strong, lightweight, flexible needled blanket intended for use as a cost-effective back-up insulation in Fiberwall® furnace linings. It is recommended for use up to 982°C (1800°F).

Duraback blanket can be installed up to four times faster than common block-type back-up insulation.

Fibermat® Blanket

Fiberfrax Fibermat is a lightweight, high-strength needled insulating blanket. The blanket fibers are spun from a ceramic composition having a normal use limit of 760°C (1400°F). Fibermat is completely inorganic and derives its exceptional strength from the needling of long ceramic fibers.

It has excellent thermal and acoustical insulating properties.

PH Blanket

Fiberfrax PH blanket is a unique product that has been specifically designed to provide excellent filtration capabilities in addition to the high chemical stability and low thermal conductivity that is possessed by all Fiberfrax products.

PH blanket is made from Fiberfrax bulk ceramic fibers in a unique wet felting process which removes unfiberized particles. In addition to the strength and resiliency afforded by the interlocking of fibers during the manufacturing process, handling strength is further enhanced by the addition of a small amount of organic binder.

A typical filtration application would involve utilizing PH blanket as a platinum catalyst recovery filter in nitric acid production. In this application, PH blanket offers numerous advantages over glass wool products including longer life, 50-60% improved filter efficiency, reduced chance of blowouts, and better temperature resistance.

Product Family Characteristics

• Excellent handling strength

• Excellent hot strength

• Low thermal conductivity

• Low heat storage

• Light weight

• Resiliency

• Thermal shock resistance

• High heat reflectance

• Excellent corrosion resistance

• Excellent thermal stability

• Excellent sound absorption

• Excellent fire protection

Specific Product Characteristics

• Extremely low shrinkage: Fibermax Mat

• Low shrinkage: Durablanket 2600 insulation

• Exceptional handling strength: Durablanket 2600 insulation,

Durablanket S insulation, Durablanket HP-S insulation, Fibermat Blanket

• Exceptional hot strength: Durablanket 2600 insulation

• Exceptional velocity resistance: Moist Pak-D insulation

• Excellent conformance to complex shapes: Moist Pak-D insulation

• Low shot content (95% fiber index): Fibermax Mat

• Exceptional sound absorption: Fibermat Blanket, PH blanket

• High resiliency: Fibermax Mat

• Excellent compression recovery: Fibermat Blanket

• Excellent filtration capabilities: PH blanket

Durablanket® 2600

• Ceramic kilns (abrasives, sanitary ware, electrical insulators, etc.)

• Billet/slab reheat furnaces

• Seals, gaskets, batten strips

• Forge furnaces

• Refractory kilns

• BOF door/shields

• Soaking pit seals

• High-temperature kilns and furnaces

• Boiler linings

• Furnace door linings and seals

• Glass furnace crown insulation

• Incineration equipment

• Skid pipe insulation

Duraback®

• Back-up for Fiberwall® lining systems

• Filler for insulating pads

• Expansion joint material

Fibermat® Blanket

• Acoustical insulation

• Thermal insulation for external applications

• Insulating pads

PH Blanket

• Catalyst recovery filter in nitric acid production

• Diffusion medium for fluidized beds

• Filtration and catalyst carrier medium for radioactive particles and hot exhaust gases

Durablanket® HP-S

Fiberfrax Durablanket HP-S insulation is a needled blanket made from spun Fiberfrax ceramic fibers. Durablanket HP-S insulation combines all of the physical characteristics offered by Durablanket S insulation in a product with a high-purity chemistry. The chemistry of Durablanket HP-S provides improved performance and service life in applications where fluxing or chemical attack occurs.

Durablanket® 2600

Fiberfrax Durablanket 2600 insulation extends the high- temperature performance of the Durablanket product line. The product is made from high-purity alumina, zirconia, and silica spun ceramic fibers. This chemical composition, manufactured in a unique fiber-making process, imparts Durablanket 2600 insulation with extremely low shrinkage characteristics at elevated temperatures.

Moist Pak-D®

Fiberfrax Moist Pak-D insulation is made from high-strength ceramic fiber blankets impregnated with inorganic bonding agents. This processing results in a flexible insulation that air dries to form a hard, rigid structure. Moist Pak-D is ideal for insulation of complex shapes and for service under condi- tions of high hot gas velocities.

The material is packaged in a clear polyethylene bag to retain the wet binder during shipment and storage. Since damage will occur, care should be taken to prevent freezing of the product.

Curing of product can be accomplished by air drying for several days or by immediate exposure to temperature in the application. Curing is merely a function of removing the water from the inorganic binder.

Fibermax® Mat

Fibermax Mat is a high-temperature, flexible mat product that is lightweight (1.5 Ib/ft3 density) and highly resilient. It is composed entirely of Fibermax polycrystalline mullite fibers to produce a product that is high-temperature (1650°C/3000°F) resistant and virtually shot-free.

Fibermax Mat contains no organic binders or other additives which cause outgassing fumes or associated problems. In addition to exhibiting excellent resistance to attack from most corrosive agents (exceptions include hydrofluoric acid, phos- phoric acid and strong alkalies), Fibermax fiber also resists oxidation and reduction.

Typical Applications

Durablanket® S and Durablanket® HP-S

• Furnace, kiln, reformer and boiler linings

• Investment casting mold wrappings

• Removable insulating blankets for stress relieving welds

• Reusable insulation for steam and gas turbines

• Flexible high-temperature pipe insulation

• Pressure and cryogenic vessel fire protection

• High-temperature kiln and furnace insulation

• Furnace door linings and seals

• Soaking pit seals

• Furnace repairs

• Thermal reactor insulation

• Expansion joint seals

• Primary reformer header insulation

• High-temperature gasketing

• Glass furnace crown insulation

• Incineration equipment and stack linings

• Annealing cover seals

• High-temperature filtration

• Nuclear insulation applications

• Atmosphere furnace lining

• Field steam generator lining

Fibermax® Mat

• Expansion joint packing

• Burner wraps

• Batten strips with fiber modules

• Aluminum homogenizing furnace linings

Moist Pak-D®

• Hot face layer for Fiberfrax heater, furnace and kiln linings where hot gas velocities exceed 12.2 m/sec (40 ft/sec)

• Hot gas duct, flue and stack linings

• Recuperator linings

• Blow pipe linings

• External and internal pipe insulation

• Reformer header insulation

• Process furnace tube weld protection

• Thermal and corrosion protection of process heater tube

supports

All heat flow factor calculations are based on a surface emissivity factor of .90, an ambient temperature of 27°C (80°F) and zero wind velocity, unless otherwise stated.

All thermal conductivity values for Fiberfrax materials have been measured in accordance with ASTM Test Procedure C-177. When comparing similar data, it is advisable to check the validity of all thermal conductivity values and ensure the resulting heat flow calculations are based on the same condition factors. Variations in any of these factors will result in significant differences in the calculated data.

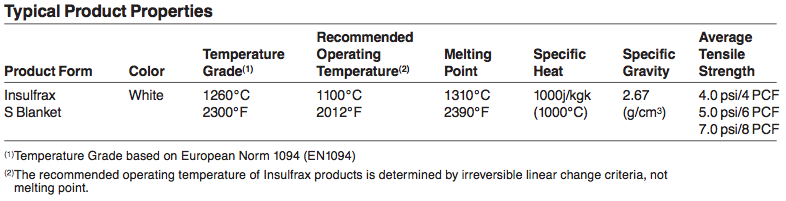

Insulfrax® S Blanket

Introduction

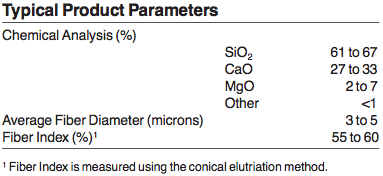

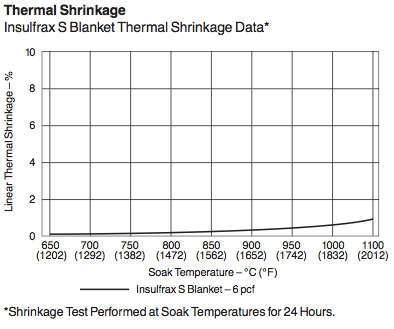

Insulfrax® S Blanket from Unifrax was developed from a calcium, magnesium, silicate chemistry to provide thermal insulation at continuous operating temperatures up to 2012°F (1100°C). Insulfrax S Blanket also meets European regulatory requirement (Directive 97/69/EC). Insulfrax S fiber chemistry has been com- bined with Unifrax’s proprietary fiber spinning technology to cre- ate a specialty high-temperature blanket with superior thermal and mechanical properties.

Insulfrax S blanket is used in a wide range of applications including refractory linings, thermal insulation, appliances, and molten metals transfer.

General Characteristics

Insulfrax S Blanket is a flexible, strong, lightweight, needled blanket produced from Insulfrax Fiber. Mechanical needling of the spun Insulfrax fibers eliminates the need for binders in the product’s manufacture and results in a product with high tensile strength. Since Insulfrax S Blanket is completely inorganic, the product exhibits no smoke generation or outgassing in service.

Insulfrax S Blanket combines low thermal conductivity with excellent resistance to thermal shock. Note that high humidity and wetting with water prior to service has little effect on Insulfrax S Blanket.

A series of green dots on the surface of the blanket make identification, tracking, and inspection of Insulfrax S Blanket simple on the job site or in the fabrication shop.

The Insulfrax Fiber calcium, magnesium, silicate chemistry provides superior wetting resistance to molten aluminum alloys. Testing with corrosive aluminum alloys at elevated tempera- tures has proven that Insulfrax fibers are superior to traditional alumina/silica refractory ceramic fibers.

Product Forms

Insulfrax S Blanket is available in the following standard forms:

• Thickness 1⁄2″, 1″, 1.5″, 2.0″

• Density 4, 6, 8, PCF

• Width 24″, 48″

• Length 12.5′, 25′

Applications

Insulfrax S Blanket is classified by Underwriters Laboratories (UL), per UL 723 (ASTM E-84). Flame Spread Rating = 0, Smoke Developed Rating = 0. High tensile strength and excel- lent thermal properties combine to make Insulfrax S Blanket the product of choice for a wide range of applications in a number of industries:

Appliances

• Residential self-cleaning ovens

• High-temperature commercial cooking appliances

Hearth Products

• Chimney Insulation

Primary Metals

• Expansion joint seals

• Aluminum transfer ladle covers

• Backup insulation for dense refractory linings

• Backup insulation for refractory ceramic fiber or

Isofrax® linings

• Maintenance blanket

• Heat shields

Metals Processing

• Stress relieving blankets

• Seals and gaskets

Petrochemical/Power

• Reusable insulating pads

• External boiler and duct insulation

Ceramic and Glass

• Glass tank crown insulation

• Expansion joints

• Carbon baking furnace covers

Health and Safety Information

Insulfrax Thermal Insulation from Unifrax, according to Directive 97/69/EC, possesses a fiber chemistry within the regulatory definition of a “man-made vitreous (silicate) fiber with random orientation with alkaline oxide and alkaline earth oxide content greater than 18% by weight.” Insulfrax fibers have been tested pursuant to EU protocol ECB/TM/26, Revision 7, Nota Q, Directive 97/69/EC, with results that are below regulatory thresholds. As a result, Insulfrax Thermal Insulation does not require additional labeling or further testing. Refer to the product Material Safety Data Sheet (MSDS) for recommended work practices and other product safety information.