Refractory Board

Introduction

Fiberfrax® Duraboard® products are a family of rigid, high- temperature ceramic fiber boards manufactured in a wet forming process using Fiberfrax alumina-silica fibers and binders. All Duraboard products offer low thermal conductivity, high temperature stability, uniform density, and excellent resistance to thermal shock and chemical attack.

They are also well-suited for applications experiencing vibration, mechanical stress and strong erosive forces. The excellent rigidity and modulus of rupture possessed by these boards makes them strong and self-supporting, yet relatively lightweight and easy to cut or machine.

These product features allow for quick, efficient handling and high installation rates, thereby enabling fast turnaround times in a variety of industrial insulation applications. Once installed, they can help reduce energy costs and cycling times due to their high insulating capability, as well as serving to protect refractory surfaces from thermal shock.

The Fiberfrax Duraboard family exhibits excellent chemical stability, resisting attack by most corrosive agents. Exceptions are hydrofluoric, phosphoric, hydrochloric and sulfuric acids as well as concentrated alkalies. Fiberfrax Duraboard products also resist oxidation and reduction. If wet by water, steam or oil, thermal and physical properties are completely restored upon drying.

In order to provide handling strength during the manufactur- ing process, small quantities of organic and inorganic binders are typically added to the board formulation. Where present, the organic binding agents burn out at temperatures between 450°F/ 232°C to 600°F/316°C during initial heat up by the end user. Following burnout of the organic binder, the boards are white in color.

Product Range

Duraboard® Products

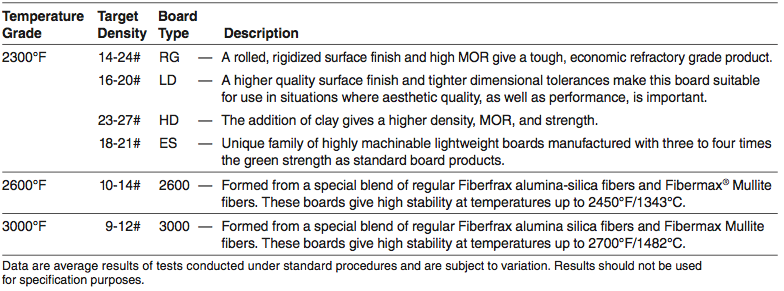

Duraboard RG

Duraboard RG (Refractory Grade) insulation is a cost-effective insulating board manufactured with the specific requirements of the refractory industry in mind. It has a rolled, rigidized sur- face which gives it a high modulus of rupture and compressive strength as well as high abrasion and hot gas erosion resistance. These properties make Duraboard RG insulation ideally suited for use both as a backup to dense refractories, such as those used in the glass industry, and as a hot face protective layer over blanket linings where the rigidized surface aids in dust suppression during both installation and operation.

Duraboard LD

This product possesses the same density and temperature rating as Duraboard RG insulation, but is manufactured to tighter dimensional tolerances and has an excellent finished surface. These characteristics make it ideally suited for use as a sandwich or core material or for use in the manufacture of components where aesthetic quality, as well as uniformity and performance, is important.

It is available in a variety of standard thicknesses ranging from =z to 2z.

Duraboard HD

Duraboard HD insulation is a high-density board product that offers the same high level of dimensional and surface uniformity as Duraboard LD insulation, but provides enhanced compressive strength and a higher modulus of rupture. This higher density is achieved through the inclusion of clay additives during the manufacturing process.

Its higher strength makes Duraboard HD insulation particularly well-suited to weight load support applications such as refractory brick backup or for covering larger unsupported spans.

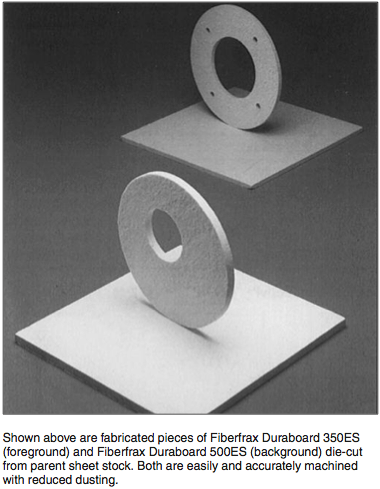

Duraboard 350ES and 500ES

These products use a unique fiber formulation to obtain high strength and machinability not normally achieved in light- weight ceramic fiber board products. The innovative compos- ite binder system using both inorganic and organic components results in a strength-to-weight ratio of more than three times that of standard refractory ceramic fiber boards. Improved physical characteristics of these products allow for easier handling and fabrication.

Duraboard 350ES has more than three times the strength of standard boards of similar densities and thicknesses. Duraboard 500ES has more than four times the strength of standard boards of similar densities and thicknesses.

Duraboard 2600

Duraboard 2600 insulation is a high-temperature insulating board designed to provide high stability at elevated temperatures. This capability is achieved by manufacturing a board formulated with a blend of Fiberfrax® alumina-silica fibers and Fibermax®, Unifrax’s patented polycrystalline mullite fibers.

This unique formulation controls thermal shrinkage to a level less than 1.0% after 168 hours at 2450°F/1343°C.

Duraboard 3000

Duraboard 3000 insulation, the highest temperature rated board manufactured by Unifrax, provides maximum high-temperature stability and shrinkage resistance. Also formulated from a blend of Fiberfrax alumina-silica fibers and Fibermax, Unifrax’s patented polycrystalline mullite fibers, Duraboard 3000 insula- tion derives its exceptional high-temperature capability from an increased Fibermax fiber concentration in the blend.

This unique formulation controls shrinkage to a level of only 1.2% after 168 hours at 2700°F/1482°C.

Inorganic Boards

Duraboard products are manufactured using a combination of both organic and inorganic binding agents. In certain applica- tions, the presence of organic binders and the low temperature burnout that is associated with them may be unacceptable. These products may be ordered with the organic binding agents already removed by heat treating following the manufacturing process. Heat treated boards display a reduced modulus of rupture and an increase in dustiness.