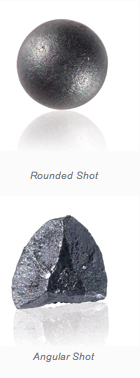

Steel Shot and Grit

Round Steel Shot

Quenched and tempered, it is a spherical product of hypereutectoid steel (C ≥ 0,85%). Perfectly controlled heat treatments provide it with optimum resilience and resistance to fatigue.This type of shot is used in all applications where the desired effect is for mass and maximum bounce as well as for shot peening.

Angular Steel Grit

A cast steel angular grit is produced by crushing specially heat treated oversize shot pellets. It is utilised for blast cleaning or surface preparation.

GP Steel Grit

Quenched and tempered, angular when new, this grit rapidly rounds off in use and is particularly suited to descaling applications.

GL Steel Grit

Quenched and tempered, although harder than GP steel grit, GL also loses its sharp edges during shotblasting and is particularly suited to descaling and surface preparation applications.

GH Steel Grit

Quenched with maximum hardness, GH always remains angular in its operating mix. These abrasives are particularly effective in surface treatment processes and produce a uniform, etched finish.

For use mainly with compressed air equipment.

WGR Steel Grits

Steel grits WGR are special products used for the cutting of hard stone products such as granite. Ask for our commercial-technical teams.

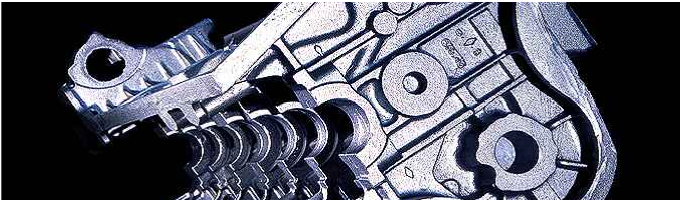

Deburring/Desanding

Melting

WS780 to WS390 shot

- Performance and ease of use

- Suited to all types of machine

HPG2 to HPG8 Premium Abrasive

- Optimum performance in terms of working life and desanding efficiency

- Improved cleanliness and appearance of blasted surfaces

- Resistance to highest throw speeds

- Technology recommended after expert appraisal of the blasting process

Applications

- Engine blocks, brake discs, HGV rear axles

- Pump bodies

- Boilers, flues

- Roadway accessories

Best Practice

33% GAIN IN PRODUCTIVITY made by HMAC (Hitachi Metals Automotive Components) on brake discs after changing to HPG4

Aluminum

WS330 to WS230 shot

- Ease of use in all types of machine

- Long working life and moderate machine wear

WGP40/WGP50 or WGL40/WGL50 Premium grit

- Improved efficiency

- Better elimination of blemishes and uniformisation of surface states

Applications

- Engine blocks, cylinder heads

- Safety hoods

Selected references

- Fonderie du Poitou

- Teksid Aluminium

- Florence et Peillon

- SAM

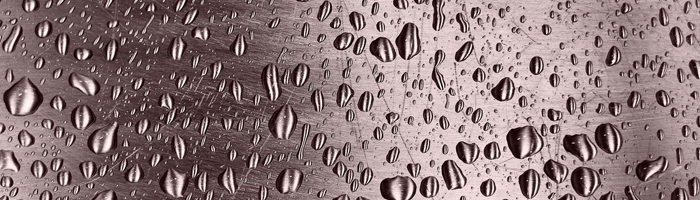

Descaling Metallurgy

WS230 to WS110 shot

- Extremely stable grain size distribution and hardness, ensuring constant control of descaling efficiency and final surface roughness.

- Ease of use in all types of machine.

Stainium Premium abrasive

- 10% increase in productivity

- Improved blasting quality: fewer blemishes

- Less roughness, ensuring better surface appearance after cold rolling

Applications

- White goods

- Chemicals and agri-food industries (containers, tanks, etc.)

Selected References

- Arcelor Mittal

- Outokumpu

- ThyssenKrupp

Surface Preparation

Steel Construction

WS460 to WS230 shot

- Ease of use in all types of machine

- Long working life and moderate machine wear

GP16 to GP40 or GL16 to GL40 grit

- Greater cleaning efficiency

- Roughness profile ensures greater adherence of paintwork and surface coatings (optimisation of peak density)

Applications

- Girders

- Welded structures

- Truck and trailer chassis

Selected References

- Arabian International Company

- Unger

- Ribouleau

- LAG

Engineering Structures

Standard WGH40/WGH50 grit for air blasting applications

- Stability of efficiency and working life

Profilium Premium abrasive

- Ready-to-use operating mix

- 20% more productivity in comparison with traditional abrasives

- Unique consistency of the surface profile

Applications

- Steel structures (bridges, reservoirs, etc. either new or undergoing renovation)

- Ships (either new or undergoing renovation)

Pipelines

WGP18/WGP25 or WGL25/WGL40 grit for surface preparation in wheel machines

- Suitable and constant roughness profile guaranteed

Profilium Premium abrasive for surface preparation by air blasting

- Ready-to-use operating mix

- Roughness profile and peak density ensuring greater adherence

- Optimum productivity and working life

Applications

- Gas and oil pipelines

Selected References

- Arabian Pipe Coating

- Altumet

- Eupec

- Volzhsky

- Chelyabinsk

- Bredero Shaw