Flasks

Spreadlock Flask

Model 1/2A

The newest complement to Fremont Flasks has already caught on rapidly. It has solved many problems, where weight has become a conscious factor in molding today. It features 1″ flanges with overall lighter construction. We have done this without sacrificing the strength of the flask. All other specifications remain the same to insure continuity.

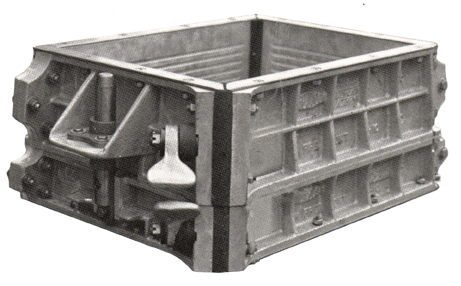

Magnesium Spreadlock Flask

Model A

The Fremont Model A Standard Spreadlock Flasks are constructed of Magnesium Metal. By using this metal, this flask is designed for heavy duty work and is comparable in weight to a medium weight flask constructed from Aluminum. Magnesium metal is particularly adapted to flask construction as it is one-third lighter in weight and at the same time has approximately twice the tensile strength.

Opening corners are operated with hardened forged cams with an aluminum lever. Replaceable live rubber inserts close the corner gaps preventing sand from lodging in the corners.

Male and female stops are inserted above and below cams giving added strength to open corners and thus maintain perfect alignment indefinitely.

The standard Model A Fremont Flask is designed for all types of machine production jobs and can also be handled on a bench.

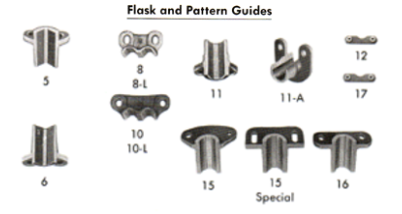

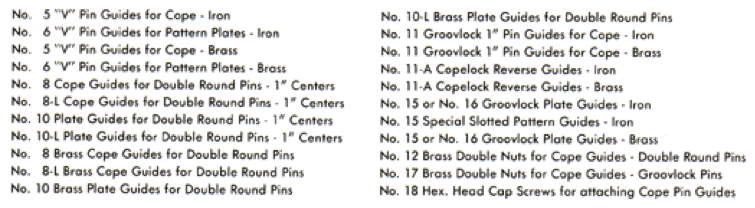

One of the outstanding features of Fremont Flasks is the 1″ Round Groovelock Pin and guide which is standard equipment on our flasks. However, Flasks can be furnished with any other type of pin and guide which a customer may prefer. The method we use in attaching the Groovelock Pin in the drag guarantees perfect alignment indefinitely under normal working conditions. The only maintenance on this type of pin and guide is an occasional adjustment of the guide to take up any slack caused by wear.

All Fremont Spreadlock Flasks are jig and fixture drilled and machined. End or side castings are easily replaced. Particular attention is called to the sturdy construction of our tight corners. These corners are assembled by inserting three No.42 dowel sleeves through which 5/16″ cap screws are inserted.

Standard Specifications

Width: 10″ to 24″ graduated in even inches

Length: 12″ to 24″ graduated in even inches

Cope Depths: 4″ to 6″ graduated in one-half inches

Drag Depths: 3″ to 6″ graduated in one-half inches

Pins: 1″ Round Groovelock with #11 Cope Guides

______________11/16″ Double Round Pins with #8-L Cope Guides

Pin Centers: For 1″ round Groovelock Pins add 3″ to length of Flask

______________11/16″ Double Round Pins can be installed on any practical centers

Flanges: Minimum 3/8″ thick x 1 3/8″ wide with top cope flange and bottom ______drag flange steel forced with 1/2″ x 1 1/4″ Cold Rolled Steel

Steel Facing: 1/8″ x 1 1/4″ steel facing is attached to top of cope and bottom of ______________drag flanges

Tapers: 3°, 4° or 5° are standard

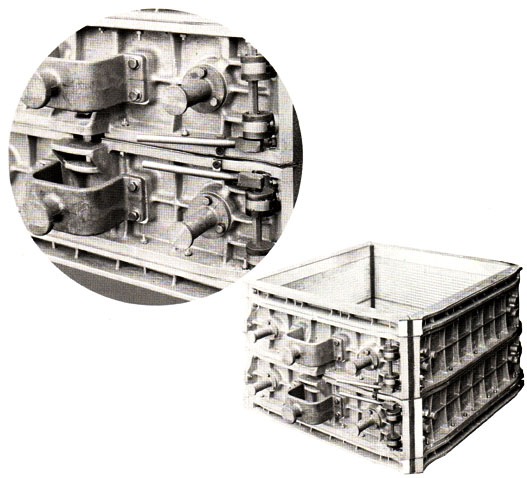

Extra Heavy Duty Spreadlock Flask

Model AA

The Fremont Model AA Extra Heavy Duty Spreadlock Flasks are constructed of Magnesium or Dowmetal exclusively. This metal is lighter and stronger than Aluminum and is particularly adapted to flask construction. These flasks are designed for all types of heavy duty production jobs and can be furnished with attachments to fit any type of molding machine.

Flanges and Ribs are extra heavy to withstand heavy pressures without bowing in the centre.

Fremont Model AA Extra Heavy Duty Flasks are equipped with one set of No. 40 cams in each open corner with No. 41-A Male and Female Stops above and below the cam. On deeper Copes and Drags, two sets of cams can be installed and if desired these can be connected with a bar and handle for simultaneous operation.

Standard Specifications

Width: 10″ to 36″ graduated in even inches

Length: 16″ to 36″ graduated in even inches (also avail. in fractional inches)

Cope Depths: 4″ to 8″ graduated in one-half inches

Drag Depths: 3″ to 8″ graduated in one-half inches

_ Model AA Spreadlock Flasks can be furnished up to 84″ lengths.

_ Copes and Drags can be furnished in one piece up to 1-” depths.

_ Upset frames must be used on any section over 10″ deep

Pins: 1″ Round Groovelock (11/16″ Double Round Pins with #8-L Cope

_ Guides can also be furnished)

Pin Centers: For 1″ round Groovelock add 3″ to length of Flask

_ 11/16″ Double Round Pins can be installed on any practical centers

Flanges: 3/8″ to 3/4″ thick x 1 3/8″ to 2″ wide depending on size of flask

Steel Facing: 1/8″ x 1 1/4″ steel facing is attached to top of cope and bottom of

_ drag flanges

Tapers: 3°, 4° or 5° are standard

Super Heavy Duty Spreadlock Flask

Model AAA

Fremont Super Heavy Duty Flasks for High Pressure Molding Machines. Available in all sizes. All 4° taper. 3″ Wide Flanges with 1/4″ steel facing strips for extra strength.

Fremont Magnesium Spreadlock Flasks are available in a full range of sizes and can be equipped with trunnions for Roto-Lift, Rol-N-Rap and Jolt’n Strip Match Plate Molding Machines.

Fremont Standard Rigid Jackets

Fremont Standard Rigid Jackets are available in either Cast Iron or Cast Aluminum.

All Fremont Jackets have a bolted corner construction. THese corners are precision machined and drilled on a jig. In side surfaces are disc ground. With this construction, replacement castings, machined and drilled ready for installation, can be furnished for broken ends or sides. Jackets otherwise scrapped can be salvaged at a very slight cost, as it is only necessary to remove a few cap screws to install a new side or end casting. Fremont Rigid Jackets can be assembled on either 3°, 4°, or 5° taper.

Fremont Ribbed Type Rigid Jackets

Fremont Ribbed or Vented Jackets are particularly designed for use in Steel Foundries. The ribbed construction permits gas to escape more readily.

Otherwise Fremont Ribbed Jackets have the same construction as the standard Jacket and are available in either Cast Iron or Cast Aluminum.

When ordering Jackets separately be sure to specify the taper, how much of the jacket is to rest above and below the parting line.

Jackets for Automated Systems

Fremont Jackets are engineered for most automated systems. The same basic high quality jacket Fremont that has been furnishing the foundry industry since 1938 is now specially designed for automated shifting devices.

Fremont jackets outperform other jackets and are field proven in reducing scrap. Jackets are jig drilled and machined for replaceable sides or ends. TIght or loose corners are available to meet your needs.

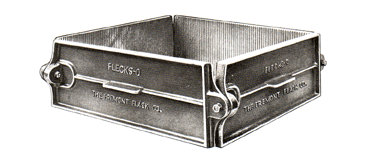

Fremont Flecks-O Jacket

The Flecks-O Jacket is assembled from four castings, so if you have the misfortune to break one of them, you need not to replace the entire jacket. COmpletely machined and drilled replacement castings can be furnished at a nominal cost. These can be installed simply by removing two special studs (part No. 50)

The Fremont Flecks-O Jacket will automatically line up with the sides of the molds made in flasks assembled by any of the standard tapers. These Jackets are available in either Cast Iron or Cast Aluminum.

When ordering Flecks-O Jackets, the only information we require is the length and width of the flask at the parting line, depth of the jacket and how much is to rest below the parting line. Also whether Cast Iron or Aluminum Jackets are desired.

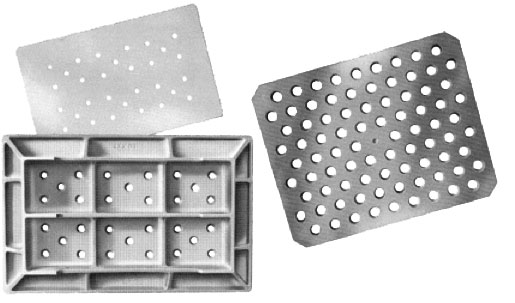

Fremont Aluminum Bottom Boards

Fremont Cast Aluminum bottom boards are a wide range of squeezer sizes.

Fremont Standard bottom boards have 3/4″ ribs and surface plate. These reinforced ribs provide added strength and rigidity in preventing mold breakage and give extra long life. Vent holes provide free venting of molds.

Fremont Standard Bottom Boards are also available with an offset flange to act as a peen and also retain mold to board.

Special Aluminum bottom boards for automated mold machining lines are also available. These high quality bottom boards are tops in the field and made to withstand the rigours of your molding operation.

Fremont Flask Part List

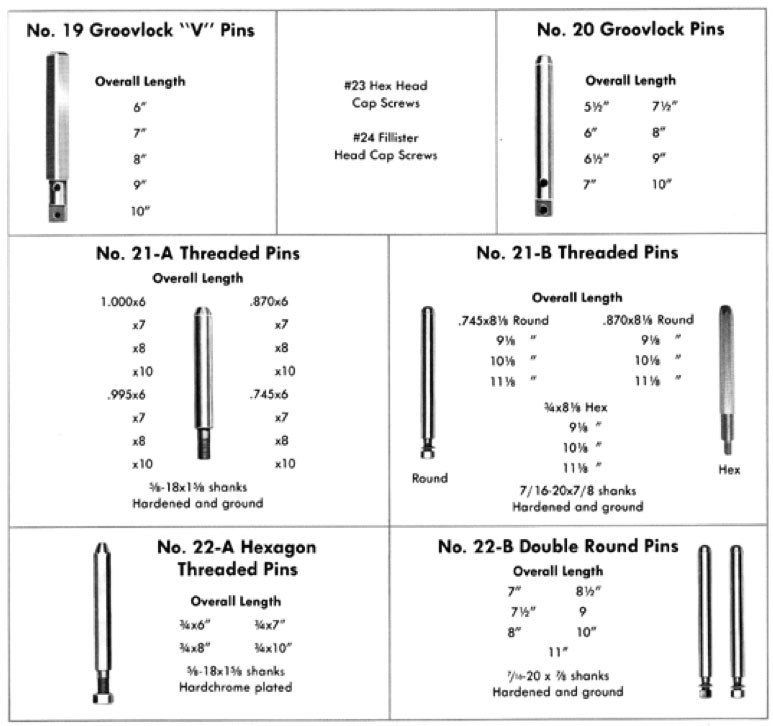

Pins For Fremont Flasks

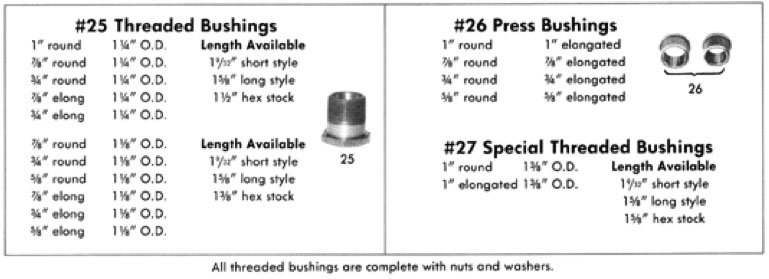

Bushings For Fremont Flasks

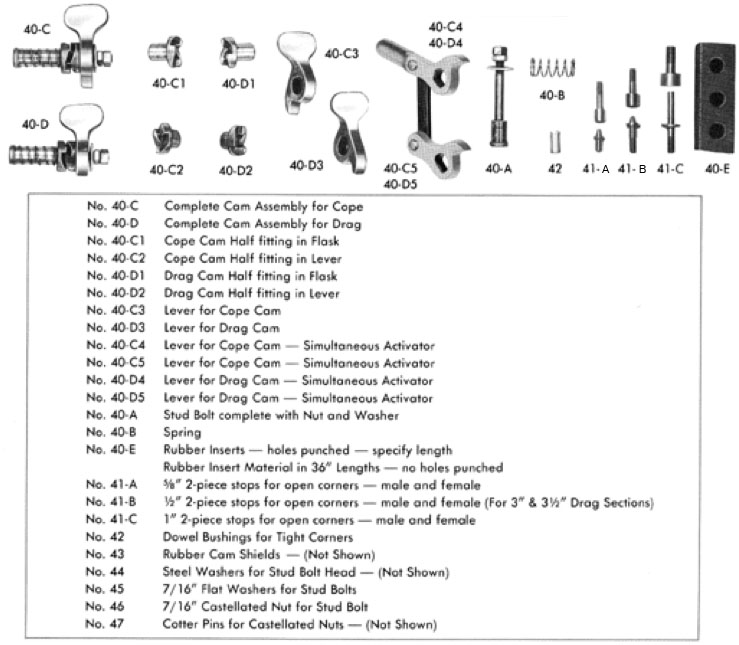

Parts For Spreadlock Flask Cam Assemblies