Riser Sleeves

Product Description

Riser Sleeves are solid cylindrical shapes, essentially comprised of various refractory powders, high temperature resistant ceramic fibres, a binder system and, when exothermic properties are exhibited, granular aluminum powders.

Purpose

To provide a means for producing sound castings of a superior quality using smaller risers than would be normally required to achieve the same results with ‘conventional’ riser systems.

Guide to Product Selection

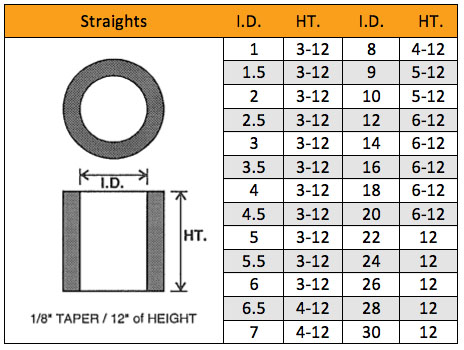

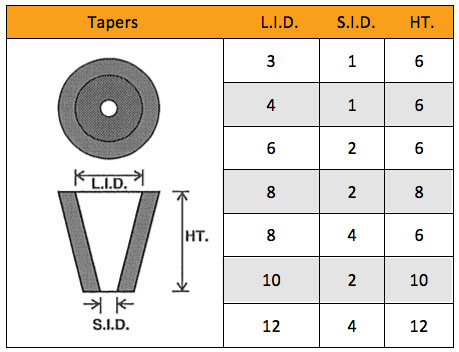

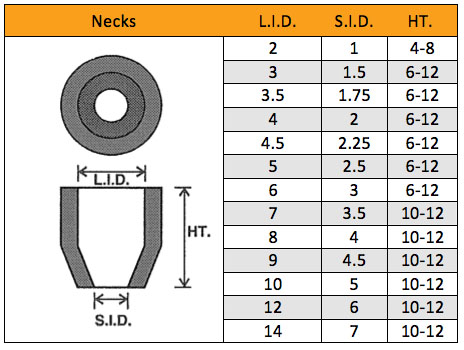

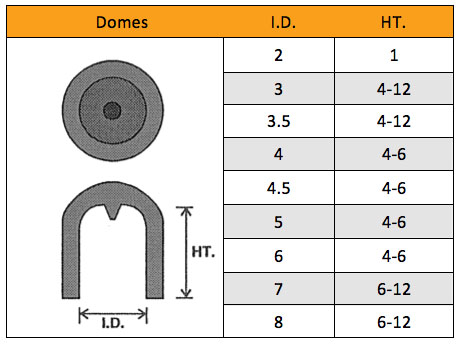

Riser Sleeves are produced in a range of compositions, shapes, and sizes for all metals and alloys. The range of compositions vary from strictly insulating through degrees of increasing exothermic reactivity while maintaining highly insulating thermal properties.

In general terms, very light weight insulating sleeves are more efficient in aluminum alloy and copper base alloy applications, while sleeves of a more robust refractory and heat producing type are more suitable in iron and steel applications. In some iron and steel applications, particular smaller castings, a lighter density type of sleeve with a relatively fast rate of heat production (HHB) for instance, may prove to be the most efficient and economical choice.

The following chart is illustrative of the recommended use of Riser SLeeves by product characteristics for various metals and section thickness of castings. However, the ingenuity of the foundryman and ability to improvise in a given set of circumstances has shown that applications are not limited to these suggestions.